Tools

One of the most important accessories that can shift how you work with CNC machines are the tools you use. Regardless of which function you’re using your CNC machines for, you’ll need a trusty tool to make your life easier – the key is knowing which tool is best suited for which project! We need to choose our tools wisely when it comes to the particular task we’re pursuing – you wouldn’t use a v-bit to mill out a deep pocket! Choose the right tool for the job or consult a professional before using one that you’re unsure of.

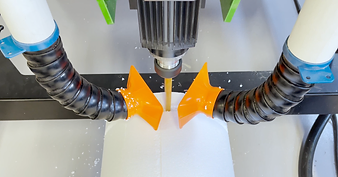

Vacuum Bed

For some materials, a vacuum bed can make or break the production process. A vacuum bed makes a variety of tasks much simpler when doing tabletop machining. It not only allows for the securing of your workpiece without the need for mechanical fixtures, but it also eliminates the need for obtrusive or dangerous clips that you’ll need otherwise. The vacuum beds on the FROGMill™ are separated by zones, which allows you to vacuum specific areas. However, use caution when using vacuum holding on the foam as it can compress the material, offsetting the tolerances once the vacuum is turned off and the foam expands. Our suggestion would be to use vacuum tables for harder substrates like sheet goods or similar materials.

Rotational Axis

Within the creative industry, it is most often likely that each project is going to be unique, and will need new machine programming due to changes in the surface geometry or end-use of the creation. A rotational axis allows for simple and efficient processing of more lucrative and complex geometry. Both our FROGMill™ and our FROGWire™ systems include a rotational axis to boost machine functionality.

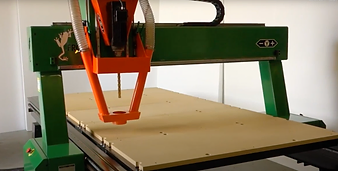

Machining Area

Finally, our preference for the machining area relies upon two important factors: stability and size. A greater gantry height will allow you to machine larger pieces. Having an extended z-stroke ensures that the tool can reach deep pockets, as well as ensuring a long milling tool can reach high enough to clear the workpiece when moving across the machining area. Our FROGMill™, for example, has a 16.5” under-gantry clearance with a 26” extended z-stroke. The steel-frame construction and high-quality drive systems work in tandem to maximize the machining area and quality resolution.