Have you ever wondered how someone constructed that trade show character, or that complex two storey lobby display? The easy answer is foam! Expanded Polystyrene foam, also known as EPS, is regarded as one of the world’s most popular materials. We use this material almost every day and may not even notice it around us. It is utilized across a range of industries due to its versatility, practicality, and durability. Foam is now used in amazing and never-seen-before creations and opens up the doors for even more elaborate ideas and designs. As a result, standard formwork has seen some decrease in popularity as it is just not flexible enough to support more sophisticated and complicated curvatures. Foam is more manageable to work with for precast shapes, and it can be machined or carved into solid structural forms instead of spending too much time and energy that goes into laminating and forming wood.

With its numerous uses and applications, EPS is hailed as a result of its superb range of properties. Read ahead to learn what makes EPS foam such a popular form material!

What Are Negative Molds?

Different manufacturing processes require the shaping of raw materials by means of a fixed tool, structure, or frame and this is known as the ‘mold’. A negative mold is concave-shaped and is designed according to the final shape that the manufacturer intends to produce. Molds are important to manufacturing processes and their main purpose is to reproduce consistent copies of the given design. Some form materials that are used in making molds can include metals, plastics, ceramics, wood, and foam among others.

What Is EPS Foam?

EPS foam has been a material of choice for several years in many industries. For example, it is utilized in food packaging applications, offers cost-effective and energy-efficient insulation in construction applications, and serves as a superb cushion in transport packaging material for fragile and shock-sensitive products. It is lightweight, durable, and offers excellent thermal insulation.

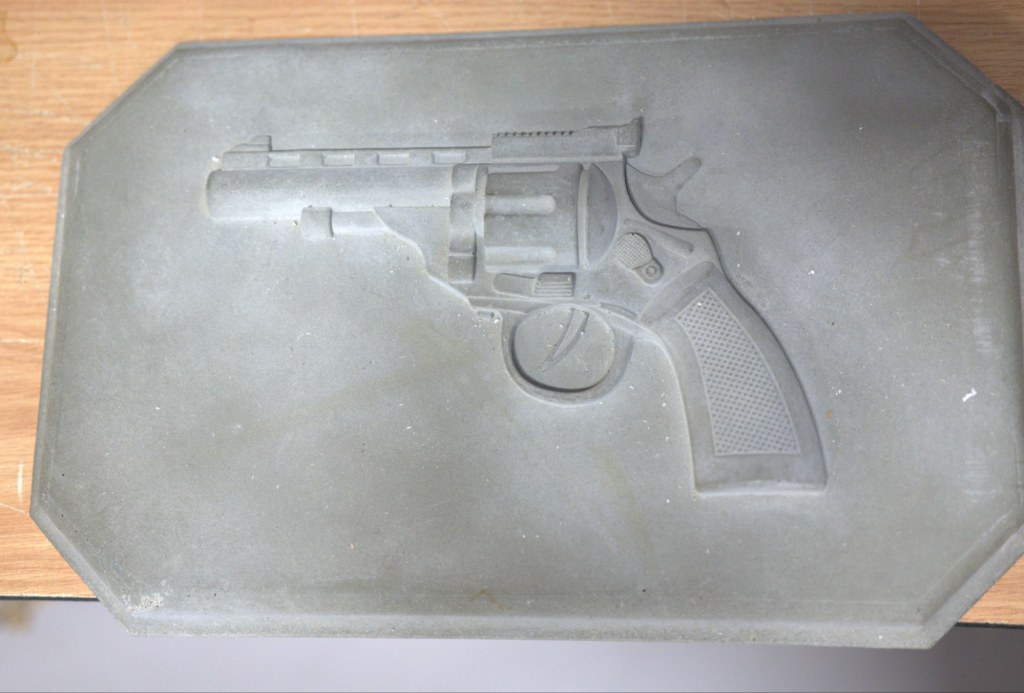

EPS foam is a white foam plastic material that is made from solid beads of polystyrene and is very lightweight with low thermal conductivity. This means its physical characteristics do not change even in high temperatures. EPS foam is 98% air, has superb cushioning properties, low moisture absorption, is non-toxic and is 100% recyclable. EPS foam can be manufactured in almost any density and shape. When used in making 3D projects, EPS can be used for making sculptures, molds, theatre props, signage, themed environments, exhibits, architectural figures and so much more.

What Are Negative Molds Used For?

There are many industries that use molds to produce their products. You may be wondering, what exactly can be made with molds? Well, just about anything! There are many reasons for using molds such as making movie props, building toys, furniture, and also automotive and construction equipment, or even if it is just replicating your favourite figurines or duplicates of family heirlooms. If there is any design that you have in mind, it can be custom cast in foam with the right processes, tools, and materials. Foam molding allows more possibilities in regard to product design and opening up new product lines. When using foam-molding processes, it is possible to produce custom-shaped parts and easily combine smaller parts into a much larger, finished design.

What Makes EPS Foam Such A Great Form Material?

Cost of Materials

There are many materials that can be used for mold-making such as paper and board. These materials are available by sheet or ply. Another example is timber, and metal-based materials can also be used. However, these materials are not very cost-efficient. Any product that is made from wood will be expensive, and when compared to standard foam materials, EPS foam is a cheaper alternative and much easier to source. However, it can be a bit tricky and cumbersome to store big blocks of EPS foam.

In addition to reduced costs, EPS foam is used routinely in the machining industry. Having materials readily available to produce a range of products permits one to keep a competitive edge in the market and allows one to take on larger and more complex projects that would normally follow with a costlier overhead. EPS foam is lightweight, making it easy to move around and relocate.

Ease Of Machining

Lighter materials are much easier to cut, and EPS foam is no exception. When compared to wood, for instance, you will need more powerful tools to cut wood than foam. Foam is easy to shape and bend. The characteristics of this material make it easier to craft unique projects, as opposed to wood which is not malleable and will not bend the way you need it to. Molds and forms that are built from wood typically require a framework and then the form surface is made of sheet lumber. This creates a problem in areas where there is more curvature than the sheet will form to, and requires other materials or processes to be implemented in specific areas of the mold and then these areas need to be blended, sanded, or filled to connect to the corresponding piece smoothly.

When using foam and foam processing equipment, you are able to manufacture your molds in fewer pieces and can approach every section using the same techniques. This allows for a more simplified process across the rest of the mold, and areas that were considered complicated when using other form materials can be easily handled with the remainder of the mold when foam is used. The use of foam blocks means that you don’t need to stick-frame a complicated enclosure or supporting structure because foam blocks back themselves up.

Availability Of Materials

Lumber prices increased by over 300% in 2022! There were some shortages in EPS foam supply, but the pricing did not change unlike lumber. This is because the EPS industry does not have the demand that can increase prices during times of shortage. It’s not likely that you will order EPS blocks from long-distance providers or order them from overseas. Generally, EPS block manufacturers are easily available and never too far away.

Cutting EPS Foam Efficiently With Hot Wire Foam Cutters

When it comes to creating advanced products, manufacturers will agree that formulating a strong design and selecting suitable materials is crucial to the project’s success. Did you know that picking the right processing technique for your materials can affect time-to-market, expenses, and overall product quality? With many types of foam available, and requiring that all materials are ready for use, there is a need for a device to sculpt them and this is where hot wire foam cutters come in.

A hot wire foam cutter is an electrical cutting tool that is used for sculpting and forming structures from foam and similar materials. This tool is made of a thin cutting wire made from hard metallic elements or metallic alloys. When activated, the wires are heated via electrical resistance to increased temperature and evaporate material as it makes contact while it passes through the wire. Since the wire is thin, the cut of the foam is accurate, smooth, and does not produce dust. When using a hot wire foam cutter, you will save a lot of time as you will spend less time cutting boards and find that there is significantly less wastage of EPS.

The way a CNC-operated hot wire cutter operates is like this: a CAD drawing or other digital representation of the project is created and then the drawing is translated into instructions. These instructions are related to speed, locations, and coordination and the machining process may need multiple routers, lathes, and other tools to separate different layers and reach the final shape. CNC machining is very precise, fast, and repeatable and is capable of achieving precise tolerances. Computer control allows the hot wire foam cutter to effectively create consistently-shaped products made out of foam.

*Project by Atomic Props and Effects https://www.nparallel.com/

FROGWire™: Foam Can Be Your friend with Streamline Automation’s FROG3D® System

The FROGWire™ is a fully automated CNC cutter. This means that the equipment is computer-driven to ensure the precision and repeatability of every contour and cut. While operating FROG3D® machines, you will never need to worry about operational dangers, manual errors, or slow turnovers that are associated with manual cutters.

Our FROGWire™ cutting machine offers an easy-to-use controller system to monitor and guide the hot wire cutting process. Files that contain 2D or 3D model designs can be imported directly to the industrial-grade G-code-based controller which supplies the machine with the toolpath automatically. The FROGWire™ can also be set up with two wires and this allows for immediate double throughput. In addition, the FROGWire™ has multi-axis capabilities and a rotational axis. Streamline Automation’s FROG3D® software can help in creating very intricate and complicated cuts in a short amount of time. This multidimensional design increases the complex structures available for cutting and forming and allows the FRO3D® system to maximize accuracy and minimize operation time and cost while doing so.

When you replace traditional methods with an automated solution, you can just think of an idea and it can be made possible to see it through without hassles and wasted time. Impressive cutting speeds mean that you can finish creating your products faster and this will allow you to increase productivity and satisfy more customers. Create greater and more complex pieces than were you capable of before, grow your product lines, and open up new markets with the FROGWire™.

Decrease Production Time

A key benefit of automated processes is that the task at hand can be performed at a constant speed for longer amounts of time. The FROGWire™ is capable of cutting a form in just a matter of minutes, compared to hours or days of framing and forming sheet goods. For example, if you need an 8” tall pillar at a diameter of 16”, the FROGWire™ can complete this by making a 2-part mold in less than 4 minutes out of a solid block of foam.

Repeatability

There is always room for error with manual processes, and every product can vary due to human error and inaccuracies. CNC machining allows for uniform products and outputs, and can perfectly match the design specifications each time they create a part.

After you are satisfied with your design, toolpath, and final product, it is simple and easy to repeat the process. You will still be able to rely on the design file being exactly the same as it was many years ago when you first accessed it. Since automation uses mechanical motion and digital information, you will not have to worry about the system going off tangent while it cuts your replica and executes your files- it does what you tell it to do, and only that!

Scalability

Scalability refers to changing the size of an object while still keeping its proportions. This means the object will look exactly the same, without any distortions, except it will just be bigger or smaller depending on what size you want it to be. Do you need a smaller version of your favourite project to display in your boardroom? Or a smaller version to include in a study model in order to get project approval? Through the use of the FROGWire™, you can utilize the same techniques to create a 1:10 version of your products without having to figure out how to build a 1:10 size framework and surface form.

Skill Level

When using FROG3D®’s hot wire foam cutter, an operator simply has to open the cutting drawings on the computer and tell the machine to start cutting. One person can effortlessly load and operate the machine. You don’t have to be an experienced cabinet maker or spend decades developing those skills yourself- chances are, if you got the job then you already have a CAD model of your final product (regardless of whether that came from the client or your in-house designers). When using foam with Streamline Automation’s FROG3D® system components, the CAD model will be your starting point and you will be able to export data directly from the design file and prompt the automation system to cut the design perfectly.

Streamline Automation will help you find the best balance between imagination and technology in the competitive world of custom fabrication. The FROG3D® System is the industry’s leading turnkey 3D CNC solution that is completely integrated and fully automated and each component works seamlessly together to deliver a complete solution. All of our equipment and products are distinctly engineered for the accurate fabrication needs of producers, regardless of the project’s scale! Our fully automated FROG3D® System will allow you to take on complex and large-scale projects that would be impossible with traditional methods, and by replacing traditional methods with an automated solution we help you turn your ideas into reality. Contact us today to learn how Streamline Automation’s FROG3D® System can help your business increase production capabilities and expand manufacturing potential.