Home » Industries » CNC in Construction and Architecture Industries

CNC in Construction and Architecture Industries

Go beyond basic architectural features with our end-to-end architectural systems that allow no creative limitations on architectural foam moldings and features.

The construction and architecture industries demand precision, efficiency, and innovation. FROG3D®’s advanced CNC technology offers the perfect solution to meet these requirements. Our equipment, including the FROGMILL™, FROGMILL™ LITE, FROGWIRE™, and FROGScan™ Flash – Peel 3, empowers businesses and manufacturers to achieve superior results in a variety of applications, from intricate architectural elements to large-scale construction projects. This page explores the role of FROG3D®’s CNC machines in transforming the construction and architecture industries.

FROG3D® CNC Equipment for Construction and Architecture

Overview of CNC Routers in Woodworking

CNC (Computer Numerical Control) technology is revolutionizing the construction industry by automating the production of complex components with unparalleled precision. In architecture, CNC machines enable the creation of intricate designs that were previously difficult or impossible to achieve manually. Our technology also aids in architectural restoration to make scanning and recreation of parts quick, accurate, and simple. FROG3D® provides cutting-edge CNC solutions tailored for construction and architectural applications, ensuring accuracy, efficiency, and flexibility.

FROGMILL™

The FROGMILL™ is a robust CNC router capable of handling large-scale woodworking projects:

- High Precision and Speed: The FROGMILL™ delivers exceptional accuracy and rapid cutting speeds, ensuring high-quality results even for intricate designs.

- Versatility: Suitable for a variety of materials, including wood, MDF, and other sheet goods.

- Advanced Software Integration: Seamlessly integrates with advanced software for precise control and automation.

FROGMILL™ LITE

The FROGMILL™ LITE offers a more compact solution without compromising on performance:

- Compact Design: Ideal for workshops with limited space, while still providing powerful cutting capabilities.

- Ease of Use: User-friendly interface and controls make it accessible for operators of all skill levels.

- Cost-Effective: Provides a budget-friendly option for businesses looking to invest in CNC technology without the high cost.

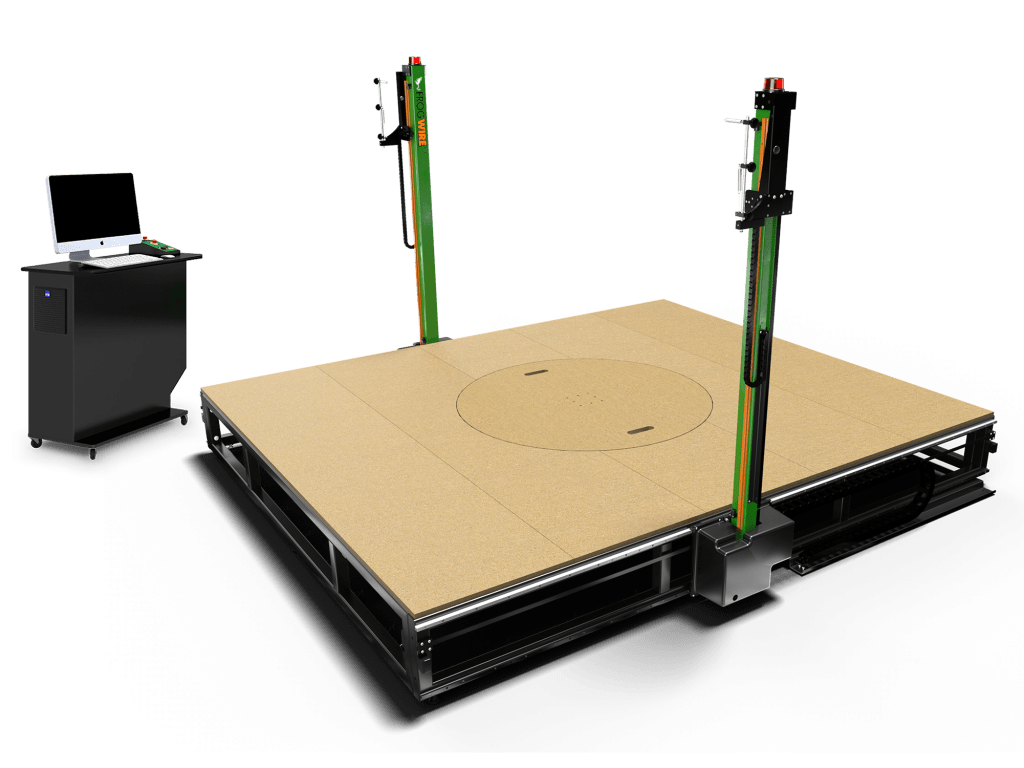

FROGWIRE™

The FROGWIRE™ is a specialized CNC hot wire cutter designed for precise shaping of foam and other lightweight materials:

- Complex Shapes: Capable of cutting intricate shapes and profiles, making it ideal for creating custom architectural forms and decorative elements.

- Ease of Use: Simple to operate, FROGWIRE™ allows for quick setup and execution, enabling rapid production of components for construction projects.

- Scalability: Perfect for both small-scale prototypes and large-scale production runs, offering flexibility for various project sizes.

FROGSCAN™ Flash - Peel 3

FROGScan™ Flash – Peel 3 enhances the CNC routing process with advanced scanning technology:

- 3D Scanning: Allows for precise measurement and replication of existing designs, ensuring perfect fit and finish.

- Integration with CNC Routers: Scanned data can be directly used to guide CNC router operations, improving accuracy and reducing setup times.

- Streamlined Workflow: Enhances overall productivity by speeding up the design-to-production process.

Optimizing Construction and Architecture with FROG3D®

Precision and Consistency

FROG3D® CNC machines provide the precision and consistency required in construction and architecture.

Accurate Reproduction: Ensures that every component matches the design specifications exactly, reducing errors and rework.

Consistent Quality: Maintains uniformity across large production runs, essential for projects that require multiple identical components.

Efficiency and Cost Savings

Implementing FROG3D® CNC technology in construction and architecture can lead to significant efficiency gains and cost savings.

Reduced Labor Costs: Automation reduces the need for skilled manual labor, lowering overall project costs.

Material Optimization: Precise cutting and shaping minimize material waste, maximizing resource utilization.

Faster Project Timelines: Increased production speed allows for quicker completion of construction and architectural projects.

Innovation and Design Freedom

FROG3D® CNC machines open up new possibilities for innovation in construction and architecture.

Complex Geometries: CNC technology enables the creation of intricate designs that are difficult or impossible to achieve with traditional methods.

Customization: Offers the flexibility to produce custom components tailored to specific project requirements, enhancing the uniqueness of architectural designs.

Applications of FROG3D®CNC Technology in Construction and Architecture

Architectural Elements

FROG3D® CNC machines are ideal for creating detailed architectural elements:

- Custom Moldings and Panels: Produce intricate moldings, panels, and decorative elements with precision and consistency.

- Large-Scale Installations: Capable of handling large projects, such as façade elements and structural components.

- Architectural Restoration: Quickly gather scanned data on-site with portable scanning technology to quickly and accurately replicate existing exterior features or keep a digital file for future use and replications.

Construction Components

In the construction industry, FROG3D® CNC equipment is used to produce a variety of components:

- Insulation and Formwork: CNC-cut foam is used for creating precise insulation and formwork elements.

- Prototyping and Models: Rapid prototyping of construction components and architectural models allows for quick design validation.

FROG3D® provides comprehensive CNC solutions for the construction and architecture industries, offering unmatched precision, efficiency, and design flexibility. Whether you are producing custom architectural elements or large-scale construction components, FROG3D®’s advanced CNC technology can significantly enhance your operations. Contact us today to learn more about how our CNC machines can transform your construction and architectural projects.

DOWNLOAD THE CONSTRUCTION & ARCHITECTURAL PRESENTATION TO EXPAND YOUR CAPABILITES WITH FROG3D®

- Reduce labor and materials costs by automating the most tedious, error-prone steps in the production process

- Take on larger and more lucrative projects than what are feasible using traditional fabrication methods

- Tackle even the most complex architectural form with total confidence

- Scan items, or whole buildings, to quickly reverse engineer components

- Digitally build in missing fragments of molding or detailing to automatically mill intricate work

NOT QUITE SURE WHAT YOU'RE LOOKING FOR?

Download our complete presentation with an overview of all applications here.