HOT WIRE FOAM

CUTTING MACHINES

A hot wire foam cutter is an electrical cutting tool for forming structures from foam and similar materials. This device consists of a thin cutting wire made of hard metallic elements or metallic alloys. When operated, wires are heated via electrical resistance to an elevated temperature, evaporating material as it makes contact as it passes through the wire. Foam products are employed over numerous industries attributing to the overall versatility and usefulness of the material itself. With various kinds of foam available and having all materials be readily usable, the need for a machine to sculpt them is evident.

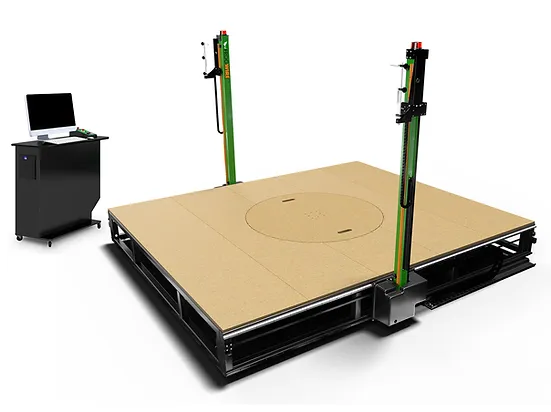

Our FROGWire™ Hot wire cutting machine employs an easy-to-use controller system to safely monitor and guide the process of hot wire cutting. Files containing the 2D or 3D model design can be directly imported to this industrial-grade G-code-based controller, supplying the machine with the toolpath automatically. Not only will automation increase efficiency, the FROGWire™ can be set up with up to two wires, instantly doubling throughput. Additionally, the FROGWire™ has multi-axis capabilities and a rotational axis. With the aid of Streamline Automation‘s advanced FROG3D® software, the FROGWire™ can produce very complicated cuts in a short amount of time. This multidimensional instrumentation design exponentially increases the complex structures available for cutting, allowing our machines to maximize precision and minimize operation time and cost.

By replacing traditional methods with an automated solution, you can turn your ideas into reality, without hassles and wasted time. Impressive cutting speeds mean finishing more products faster, letting you ramp up productivity and satisfy more customers. Create larger, more intricate pieces than you were capable of before. Grow your product lines and open up new markets.

To learn more about how Streamline Automation‘s FROG3D® systems may help you and your organization increase production capability and expand manufacturing capability, contact us today or see samples of our customers work here.

Related Products

SEND ME

FROGWIRE™

Product Sheet