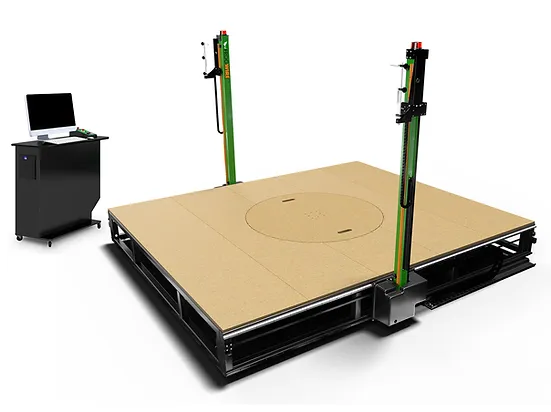

5-AXIS CNC HOT WIRE FOAM CUTTER

Our advanced CNC hot wire foam cutting machine allows you to prepare foam for detailed milling or to cut stunning final products.

FROGWIRE™

Specifications

| Metric | Standard | |

| Overall Length: | 2997 mm | 118” |

| Overall Width: | 2591 mm | 102” |

| Table Height: | 1956 mm | 77” |

| Process Area Length: | 2515 mm | 99” |

| Process Area Width: | 2464 mm | 97” |

| Process Area Height: | 1321 mm | 52” |

| Total Weight: | 340 kg | 750 lbs |

| Maximum Cutting Speed: | 21 mm/s | 50″/min |

| Maximum Rapid Traverse Speed: | 1185 mm/s | 2800 IPM |

| Accuracy: | 0.025 mm | 0.001” |

| Repeatability: | +/-0.05mm | +/-0.002” |

| Motors: | Servo Motors | |

| Motion: | Pinion and Steel reinforced drive belts on all axes | |

| Network: | TCP/IP, 10Base2 or 10BaseT | |

Key Features

Boasting industrial strength construction along with top of the line speed, accuracy and capable of 2D, 3D, flat cuts and rotational parts by importing vectors or 3D STL models.

By replacing traditional methods with an automated solution, you can turn your ideas into reality, without hassles and wasted time. Impressive cutting speeds means finishing more products faster, letting you ramp up productivity and satisfy more customers. Create larger, more intricate pieces than you were capable of before. Grow your product lines and open up new markets.

Easy to Use Controller System

Full control is provided with an industrial G-code based controller system with hand-held pendant. Import DXF files for 2D cutting along with multiple file imports for 3D cutting. Tool path G-code files directly.

Independent Axis and Multi-Wire

Everything you need for fast and efficient cutting, opening doors to a range of new creations. Allows use of up to 2 wires.

Fast Cutting Speeds

FROGWire™ features rapid travel (2800 IPM) and a maximum cutting speed of 50” per minute, based on Type 1 EPS.

Industrial Strength Construction

FROGWire™ defines durability with heavy-duty welded aluminum construction.

Servo Motors

Heavy-duty servo motors independently drive all axes, offering high speed with accuracy and reliability.

2, 3 and 4-axis hot wire cuts

Easily create complex tapered parts using the advanced tapered cutting capabilities. Create multi-sided cuts using multiple profile

shapes created from a 3D model.

End-to-End Automation

FROGWire™ has been designed to work seamlessly with other FROG3D™ components, eliminating the hassles that come with non-integrated components.

Comprehensive Training and Support

Streamline backs up each of our products with second-to-none training programs and technical support to get you up and running quickly.

Related Products

What can you cut with FROGWire™?

SEND ME

FROGWIRE™

Product Sheet