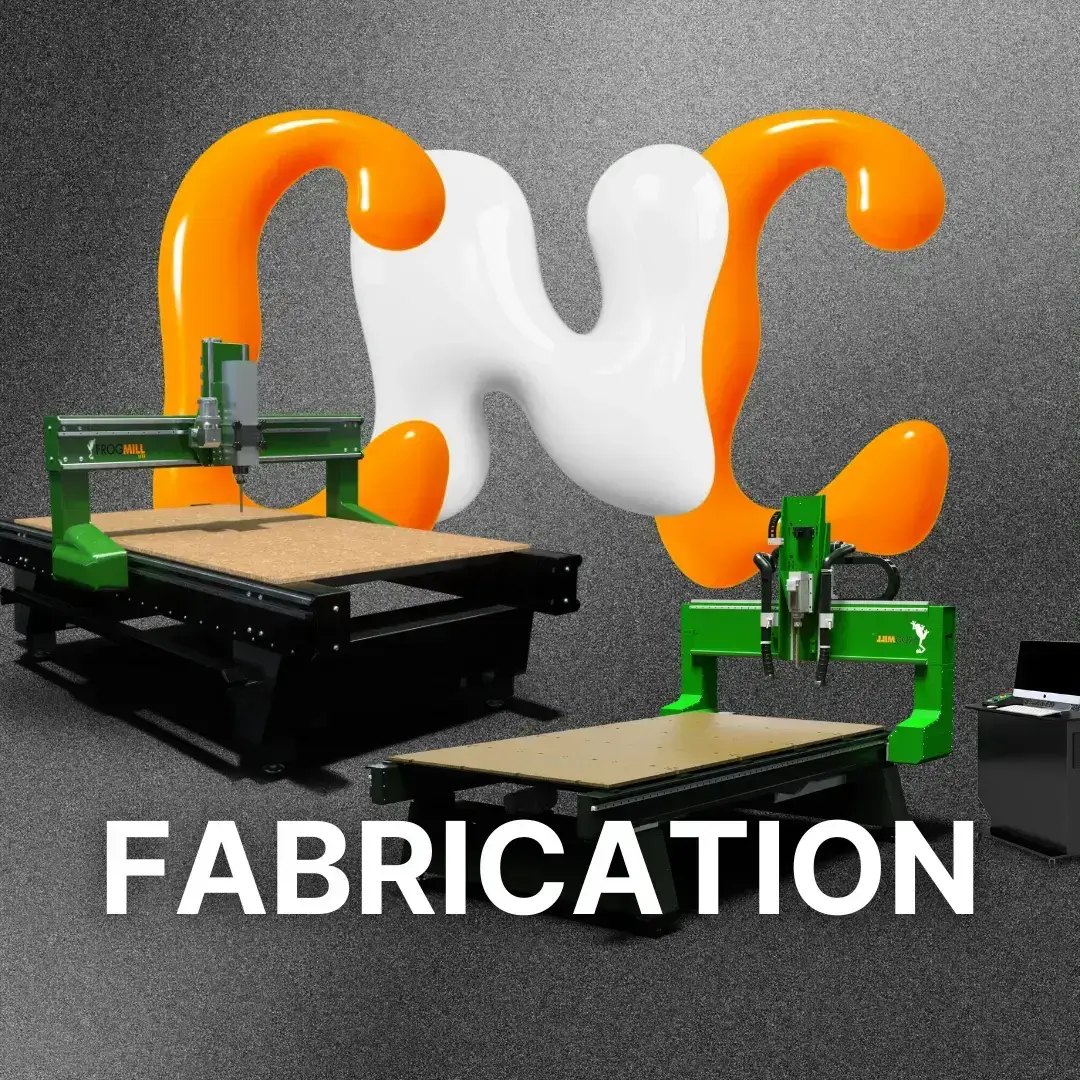

FROG3D® offers advanced CNC cutting machines that bring exceptional precision and versatility to a wide range of applications. Our equipment is designed to streamline production processes, allowing for rapid prototyping, detailed sculpture fabrication, and efficient mold making.

The machines are built with commercial-grade construction and cutting-edge technology, ensuring both durability and high performance. Supported by industry-leading training and support, FROG3D®’s CNC solutions empower users to achieve intricate designs and high-quality outputs, making them a valuable asset for various industries.

Equipment

FROG3D® brings advanced 3D fabrication capabilities to your production challenges. Creative, adaptive, exceptional, our turnkey 3D CNC fabrication system gives you the tools to work bigger, better, and faster. With cutting-edge technology, commercial-grade construction and industry leading training and support, FROG3D® bridges the gap between your creative process and production needs.

What is a CNC Cutting Machine?

CNC (Computer Numerical Control) cutting machines are automated devices that use computer programming to control machining tools. These machines are capable of cutting, shaping, and engraving various materials, including wood, composites, acrylic, and various foams including both EPS and HDU in numerous densities, with high precision and efficiency.

CNC cutting machines are widely used in manufacturing, prototyping, and production environments due to their ability to consistently produce complex and accurate designs. By automating the cutting process, these machines enhance productivity and reduce the likelihood of human error.

Key Benefits of CNC Cutting Machines from FROG3D®

- High Precision and Efficiency: Ideal for detailed and complex projects.

- Robust Construction: Designed to handle rigorous use and provide consistent performance.

- Software Compatibility: Seamless integration with industry-standard CAD/CAM software for smooth workflows.

- Extensive Support and Training: Helps users maximize the potential of their machines.

Applications of CNC Cutting Machines

- Aerospace: Precision parts for aircraft and spacecraft

- Automotive: Engine components and body parts

- Construction: Concrete forms and building materials

- Packing:: Molded protective layers for fragile goods, for example, TV packaging

- Architecture: Unlimited architectural foam moldings and features

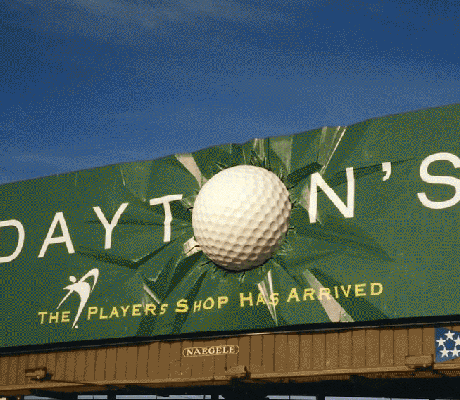

- Sculptural Fabrication: Perfect replicas and enlargements of artwork

Industry Applications

How to Choose the Right CNC Milling Machine?

- Spindle Speed and Power: Essential for handling tougher materials and increasing cutting speed.

- Travel Dimensions:This must accommodate the sizes of your parts.

- Tool Capacity:Enables complex operations without frequent tool changes.

- Software Compatibility: Ensures smooth integration with CAD/CAM software.

FROGMill™ VS FROGMill™ Lite VS FROGWIRE™: What is the Difference?

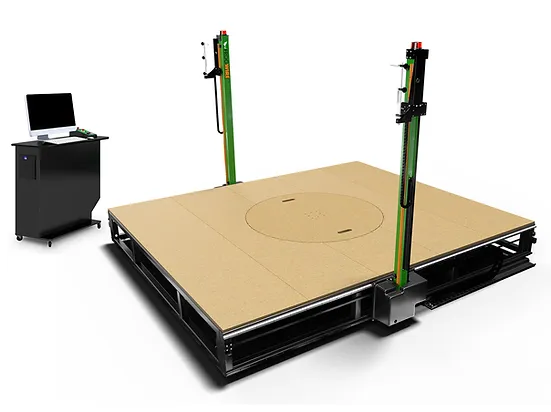

FROGMill™

Specifications

| Metric | Standard | |

| Overall Length: | 366 cm | 144.13″ |

| Overall Width: | 222 cm | 87.56″ |

| Overall Height: | 242 cm | 95.31″ |

| Weight: | 1134 kg | 2500lbs |

| Process Area L x W: | 315 cm x 162.5 cm | 124″ x 64″ |

| Under Gantry Clearance: | 40.6 cm | 16″ |

| Z-Axis Stroke: | 66 cm | 26″ |

| Maximum Cutting Speed: | 432 mm/s | 1000 IPM |

| Maximum Traverse Speed: | 508 mm/s | 1200 IPM |

| Accuracy: | 0.025 mm | 0.001″ |

| Repeatability: | +/-0.05mm | +/-0.002″ |

| Maximum Column Diameter: | 116 cm | 46″ |

| Maximum Column Length: | 252 cm | 99.5″ |

| Motors: | Servo Motors | |

| Motion: | Rack & Pinion on all axes | |

| Network: | TCP/IP, 10Base2 or 10BaseT | |

| Spindle Horsepower: | 5.5 hp with max 1″ collet size | |

| Electrical Specifications: | 208-240V, 30 Amp, 3 ph 50/60 Hz | |

Key Features

The FROGMill™ is the most powerful 4-axis CNC router available. Combined with industrial strength, unequalled quality and precision, the FROGMill™ provides you the capabilities you need to create larger and more intricate pieces.

The 4th axis offers index cutting capabilities to create full 3D carvings (up to a 4’ diameter and 8’ length) from a single piece. Mounting directly onto FROGMill™, the 4th axis rotational capabilities lets you go from ‘art to part’ in the shortest amount of time possible. The FROGMill™ 4-axis CNC router creates production efficiencies, but it also provides the accuracy and detail you need to create stunningly detailed projects.

FROGMill™ Lite

Specifications

| Overall Length: | 121″ |

| Overall Width: | 73” |

| Overall Height: | 72” |

| Process Area (L x W): | 100”x 56” |

| Under Gantry Clearance: | 12” |

| Z-Axis Stroke: | 12.5” |

| Maximum Traverse Speed: | 800 IPM |

| Accuracy: | + 0.001 in |

| Repeatability: | + 0.002 in |

| Maximum Column Diameter: | 36” |

| Maximum Column Length: | 72” |

| Motors: | Servo |

| Motion: | Rack & Pinion on all Axes |

| Spindle Horsepower: | 5 hp with max 3/4” collet size |

| Electrical Specifications: | Single Phase Power (230 volt 30 Amp) |

Key Features

Perfect for fabricators and start-ups with moderate production needs, budgets or limited shop space and boasting the same exceptional quality, training and support that defines all FROG3D® products. Compact CNC router FROGMill™ Lite gives you the tools to drive production, expand capabilities, and grow your bottom line.

Optional 4th axis allows you to add functionality down the line, while a single-phase power supply makes FROGMill™ Lite easy to install in any space. Replace onerous manual processes with an automated solution, take on larger, more lucrative projects, and achieve stunning results with a solution that is designed to grow with your business.

FROGWIRE™

Specifications

| Metric | Standard | |

| Overall Length: | 2997 mm | 118” |

| Overall Width: | 2591 mm | 102” |

| Table Height: | 1956 mm | 77” |

| Process Area Length: | 2515 mm | 99” |

| Process Area Width: | 2464 mm | 97” |

| Process Area Height: | 1321 mm | 52” |

| Total Weight: | 340 kg | 750 lbs |

| Maximum Cutting Speed: | 21 mm/s | 50″/min |

| Maximum Rapid Traverse Speed: | 1185 mm/s | 2800 IPM |

| Accuracy: | 0.025 mm | 0.001” |

| Repeatability: | +/-0.05mm | +/-0.002” |

| Motors: | Servo Motors | |

| Motion: | Pinion and Steel reinforced drive belts on all axes | |

| Network: | TCP/IP, 10Base2 or 10BaseT | |

Key Features

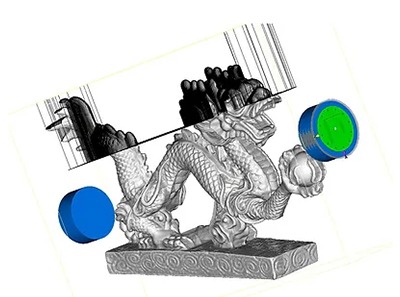

Boasting industrial strength construction along with top of the line speed, accuracy and capable of 2D, 3D, flat cuts and rotational parts by importing vectors or 3D STL models.

By replacing traditional methods with an automated solution, you can turn your ideas into reality, without hassles and wasted time. Impressive cutting speeds means finishing more products faster, letting you ramp up productivity and satisfy more customers. Create larger, more intricate pieces than you were capable of before. Grow your product lines and open up new markets.

FROG3D® Software for CNC Cutting

Whether you’re creating themed environments, exhibits, props, signage, sculptures, or intricate fabrication projects, our software suite empowers you to design impressive 3D projects with superior accuracy, detail, speed, and flexibility over traditional sculpting methods.

Our software offers advanced 3D design features, including scanning and 3D model editing, and tool path functionalities, ensuring your designs are flawless and ready for precise foam reproduction.

Optimized for FROG3D®’s CNC cutting machines, our software is backed by industry-leading training and support, enabling our clients to achieve and surpass their production objectives.

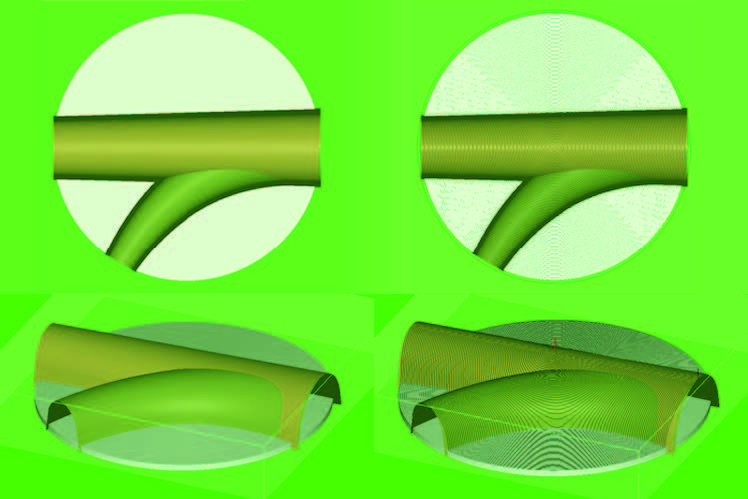

Create 2,3 and 4-axis Hot Wire Cuts

A comprehensive software designed to easily create 2,3 and 4-axis cutting programs for the FROGWire™.

Revolutionize Your CNC Machining Strategy

FROG3D® Training and Support

At Streamline Automation, we are dedicated to setting our clients up for success. Our work spans various roles, industries, and applications, allowing us to meet your most pressing business and personal needs. We look forward to helping you achieve your business goals and are excited to collaborate. The custom fabrication market is highly competitive, and we have the expertise to help you overcome upcoming challenges.

Whether you’re a hobbyist or a professional, Streamline Automation offers extensive training programs in custom fabrication. With almost 25 years of experience, our industry experts provide unparalleled knowledge and hands-on experience, ensuring you have everything you need to bring your ideas to life.

In addition to safe operation training for our FROG3D® machines, we offer in-depth process training to help you create your projects. Our comprehensive training regimen makes the FROG3D® fabrication system ideal for companies starting with CNC machinery, or seasoned users.

To learn more about how Streamline Automation can help you increase production and expand manufacturing capabilities, contact us or explore our work samples here.

Related Products

Related Articles

FAQs about CNC Cutting Machines

A CNC cutting machine uses computer numerical control to precisely cut various materials based on programmed instructions. It automates the cutting process for enhanced accuracy, speed, and efficiency.

For small businesses looking to elevate their production efficiency, a compact, versatile CNC machine that balances affordability and functionality is often the best choice, such as the FROGMill™ Lite.

The cost of a quality CNC machine depends on the size, features, training requests, and capabilities required. To get a price for FROG3D®’s CNC cutting machine configured specially for your needs, contact us.

CNC machines can last anywhere from 10 to 20 years or more with proper maintenance and regular use. With Streamline Automation’s Trade-In Trade-Up Program, you can choose to trade in your previous models for the newest models, sell your system back to us, or upgrade your existing Systems to ensure you are always working with the latest technology.

CNC machines are user-friendly and come with detailed instructions and support. While there is a learning curve, many users find it easy to operate with proper training. Streamline Automation’s training programs ensure success across all skill levels.

CNC cutting machines can cut a wide range of materials, including wood, metal, plastic, various types and densities of foam, and composites, making them highly versatile for various applications.

Where Can You Buy CNC Cutting Machines?

Many companies deal in CNC cutting machines. As Canada’s leading CNC fabrication machines manufacturer, FROG3D® offers high-quality CNC cutting machines in different sizes and configurations to meet your needs. You can browse our product catalog or fill out the contact form for more detailed information.