FROG3D®’s CNC milling machines offer advanced technology suited for any manufacturing process, whether it involves high-volume production or intricate one-off pieces requiring multi-axis procedures.

Our Canadian-made 4-axis foam CNC milling machines, the FROGMILL™ and FROGMILL Lite™, are designed with industrial-grade strength, unparalleled quality, and precision. These machines empower you to create larger, more complex fabrications with ease, ensuring both efficiency and exceptional detail in every project.

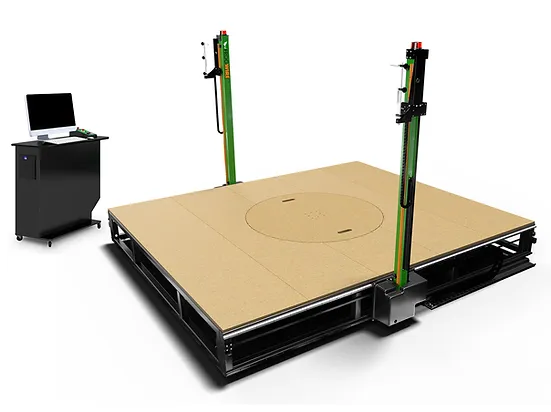

FROGMill™

4-axis CNC foam carving router

Industry’s most powerful 4-axis CNC foam carving router, giving you capabilities impossible with traditional processes or lesser machines.

FROGMill™ Lite

Compact 4-axis CNC router

Delivering a wide range of functionality at a compelling price-point.

CNC milling machines are indispensable for both commercial and industrial production, benefiting industries such as aerospace, medical, and precast. But how do these machines operate, and what makes them unique? CNC stands for Computer Numerical Control, indicating that the machine is directed by numerical computer control rather than manually. These tools perform precision machining processes akin to drilling and cutting, eliminating human error. This increasingly popular industrial solution can handle a variety of materials with exact sizes and shapes, for example, foam, plastic, and wood.

Benefits of CNC Milling Machines from FROG3D®

Enhanced Performance

Leveraging high-speed, high-accuracy technology, FROG3D®’s CNC milling machines enhance productivity and machining quality.

Unmatched Reliability

FROG3D®’s Canadian-manufactured CNC products undergo stringent testing to ensure durability and maximize machine uptime.

Superior Quality Parts

With advanced CPUs, FROG3D®’s controls deliver excellent surface quality and increased work throughput.

Comprehensive Support

FROG3D®’s commitment to ongoing product support and exceptional customer service makes our CNC milling machines the preferred choice for users worldwide.

Applications of CNC Milling Machines

CNC milling machines are used in various applications, including:

- Aerospace: Precision parts for aircraft and spacecraft

- Automotive: Engine components and body parts

- Construction: Concrete forms and building materials

- Medical: Medical device prototypes such as prosthetic limbs and orthotics

- Architecture: Unlimited architectural foam moldings and features

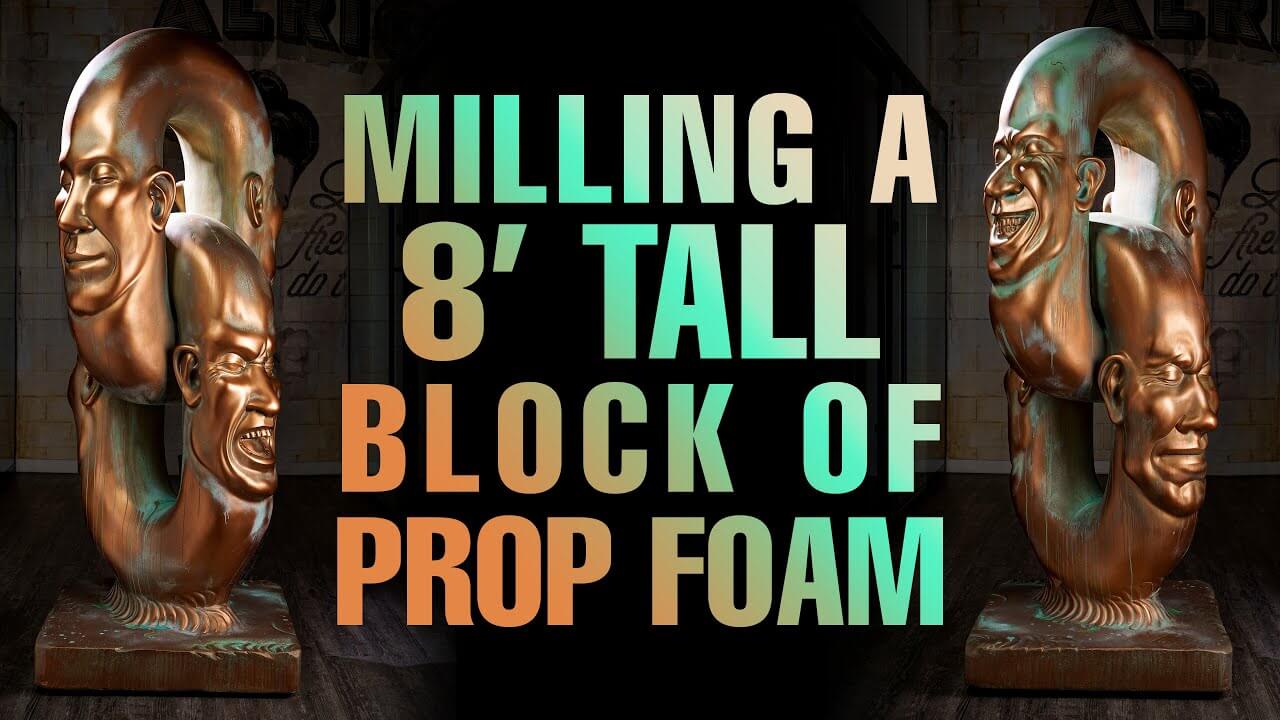

- Sculptural Fabrication: Perfect replicas and enlargements of artwork

How to Choose the Right CNC Milling Machine?

- Spindle Speed and Power: Necessary for tougher materials and faster production.

- Travel Dimensions: Ensure they accommodate your part sizes.

- Tool Capacity: Allows for complex operations without frequent tool changes.

- Software Compatibility: Seamless integration with CAD/CAM software.

FROGMill™ VS FROGMill™ Lite: What is the Difference?

FROGMill™

Specifications

| Metric | Standard | |

| Overall Length: | 366 cm | 144.13″ |

| Overall Width: | 222 cm | 87.56″ |

| Overall Height: | 242 cm | 95.31″ |

| Weight: | 1134 kg | 2500lbs |

| Process Area L x W: | 315 cm x 162.5 cm | 124″ x 64″ |

| Under Gantry Clearance: | 40.6 cm | 16″ |

| Z-Axis Stroke: | 66 cm | 26″ |

| Maximum Cutting Speed: | 432 mm/s | 1000 IPM |

| Maximum Traverse Speed: | 508 mm/s | 1200 IPM |

| Accuracy: | 0.025 mm | 0.001″ |

| Repeatability: | +/-0.05mm | +/-0.002″ |

| Maximum Column Diameter: | 116 cm | 46″ |

| Maximum Column Length: | 252 cm | 99.5″ |

| Motors: | Servo Motors | |

| Motion: | Rack & Pinion on all axes | |

| Network: | TCP/IP, 10Base2 or 10BaseT | |

| Spindle Horsepower: | 5.5 hp with max 1″ collet size | |

| Electrical Specifications: | 208-240V, 30 Amp, 3 ph 50/60 Hz | |

Key Features

The FROGMill™ is the most powerful 4-axis CNC router available. Combined with industrial strength, unequalled quality and precision, the FROGMill™ provides you the capabilities you need to create larger and more intricate pieces.

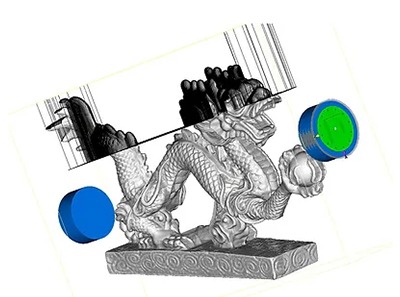

The 4th axis offers index cutting capabilities to create full 3D carvings (up to a 4’ diameter and 8’ length) from a single piece. Mounting directly onto FROGMill™, the 4th axis rotational capabilities lets you go from ‘art to part’ in the shortest amount of time possible. The FROGMill™ 4-axis CNC router creates production efficiencies, but it also provides the accuracy and detail you need to create stunningly detailed projects.

FROGMill™ Lite

Specifications

| Overall Length: | 121″ |

| Overall Width: | 73” |

| Overall Height: | 72” |

| Process Area (L x W): | 100”x 56” |

| Under Gantry Clearance: | 12” |

| Z-Axis Stroke: | 12.5” |

| Maximum Traverse Speed: | 800 IPM |

| Accuracy: | + 0.001 in |

| Repeatability: | + 0.002 in |

| Maximum Column Diameter: | 36” |

| Maximum Column Length: | 72” |

| Motors: | Servo |

| Motion: | Rack & Pinion on all Axes |

| Spindle Horsepower: | 5 hp with max 3/4” collet size |

| Electrical Specifications: | Single Phase Power (230 volt 30 Amp) |

Key Features

Perfect for fabricators and start-ups with moderate production needs, budgets or limited shop space and boasting the same exceptional quality, training and support that defines all FROG3D® products. Compact CNC router FROGMill™ Lite gives you the tools to drive production, expand capabilities, and grow your bottom line.

Optional 4th axis allows you to add functionality down the line, while a single-phase power supply makes FROGMill™ Lite easy to install in any space. Replace onerous manual processes with an automated solution, take on larger, more lucrative projects, and achieve stunning results with a solution that is designed to grow with your business.

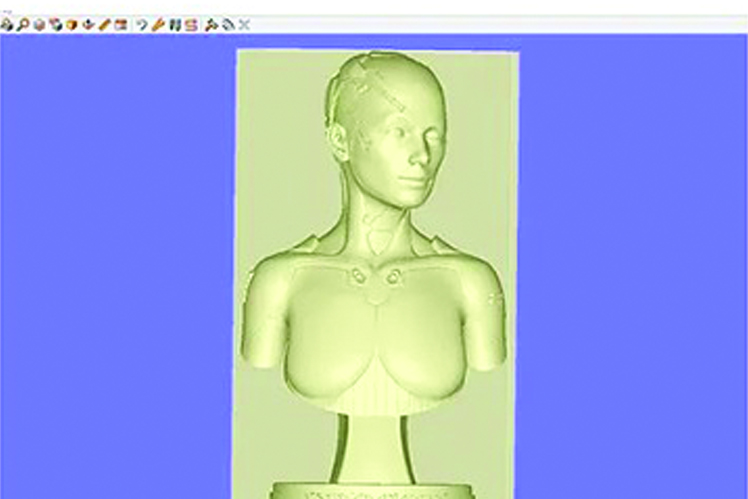

FROG3D® Software for CNC Milling

Whether you’re crafting themed environments, exhibits, props, signage, sculptures, or complex fabrication projects, our comprehensive software suite enables you to design stunning 3D projects with unmatched accuracy, detail, speed, and flexibility compared to traditional sculpting methods.

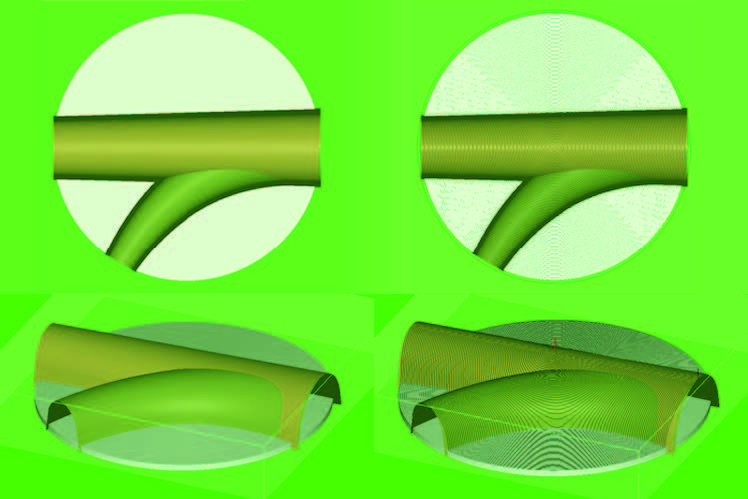

Our software includes advanced 3D design capabilities along with scanning, editing, and tool path functionalities, ensuring your designs are perfected and ready for precise foam reproduction.

Designed to maximize the capabilities of FROG3D®’s CNC milling machines, our software is supported by industry-leading training and support, helping our clients meet and exceed their production goals.

Create 2,3 and 4-axis Hot Wire Cuts

A comprehensive software designed to easily create 2,3 and 4-axis cutting programs for the FROGWire™.

Revolutionize Your CNC Machining Strategy

FROG3D® Training and Support

At Streamline Automation, we are dedicated to setting our clients up for success. Our work spans various roles, industries, and applications, allowing us to meet your most pressing business and personal needs. We look forward to helping you achieve your business goals and are excited to collaborate with you. The custom fabrication market is highly competitive, and we have the expertise to help you overcome upcoming challenges.

Whether you’re a hobbyist or a professional, Streamline Automation offers extensive training programs in custom fabrication. With almost 25 years of experience, our industry experts provide unparalleled knowledge and hands-on experience, ensuring you have everything you need to bring your ideas to life.

In addition to safe operation training for our FROG3D® machines, we offer in-depth process training to help you create your own projects. Our comprehensive training regimen makes the FROG3D® fabrication system ideal for companies starting out with CNC machinery.

To learn more about how Streamline Automation can help you increase production and expand manufacturing capabilities, contact us or explore our work samples here.

Related Products

Related Articles

FAQs about CNC Milling Machines

CNC milling machines operate by following programmed instructions to move the cutting tool along multiple axes, shaping the workpiece as required.

Where Can You Buy CNC Milling Machines?

Many companies deal in CNC milling machines. As Canada’s leading CNC fabrication machines manufacturer, FROG3D® offers high-quality CNC milling machines (4-axis) in different sizes and configurations to meet your needs. You can browse our product catalog or fill out the contact form for more detailed information.