Machine tools are used for forming, cutting, and carving materials and are essential parts of the manufacturing process. At FROG3D®, we offer specialized CNC router bits for foam and alternative materials like wood and plastics such as polypropylene. Specialized router bits are important because different materials require specialized tooling approaches for maximum results. The correct CNC machine tools are important to increase manufacturing productivity, allow extreme precision and accuracy, ensure flexible production, and make sure products are consistent each time.

Router Tools for CNC Routing

CNC is the acronym for Computer Numerical Control and is a platform that controls machine tools through a computer program. CNC programming of machines offers the advantages of computer precision over manual control. CNC routing is one of several advanced machining applications operated by a computerized, automated process that controls the motion of tools for shaping, machining, cutting, or removing material used in manufacturing products.

CNC routers are a popular application for CNC machining platforms. As an advanced type of tooling method, CNC routers work with Computer Aided Manufacturing (CAM) software programs, which is a visual programming tool used to create geometric code or more simply known as g-code, which is the CNC computer language that operates CNC machines. The g-code controls the basic movement, time, and direction of the tool heads of the machines.

How Does A CNC Router Work?

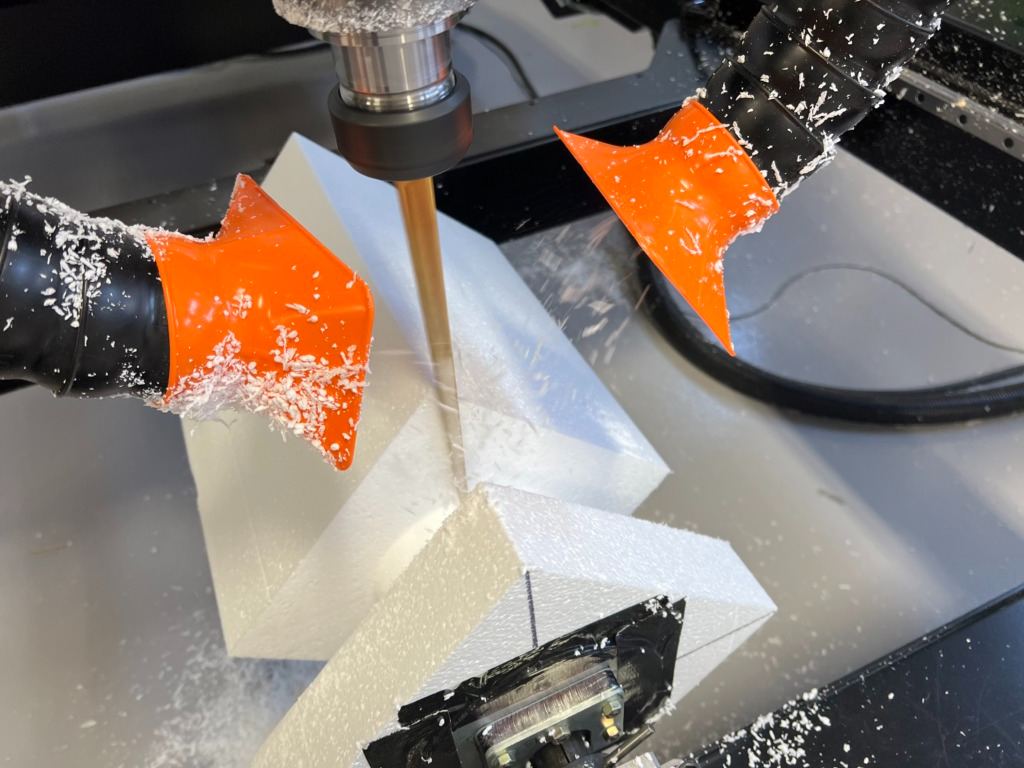

CNC routers have similar functions to handheld routers as they are tools that are used to cut different shapes into various materials for different purposes. Although similar to handheld routers, CNC routers are stronger and more versatile machines that can cut many more materials with precision. A CNC router can use computer numerical control to automate the route of the tool paths that in turn enable the machine to function. With these capabilities, CNC routers are able to offer much more effective cuts than manual-controlled routers do with a noticeable increase in productivity and efficiency.

Similar to other CNC machine applications, CNC routers are able to produce an exceptional variety of customized parts with precision. Once programmed, a single set of prompts can accomplish three-dimensional cutting tasks for a variety of materials. Automation provides ease of operation and provides results such as improved production capacity, less waste, repeatability, and safety.

CNC routers need bits, and these bits shape the carving type, resolution, and material. Without the right bits, even the most perfect CNC machine won’t be able to produce well. CNC machines have unlocked all kinds of creative possibilities, however, the magic lies in the bit. It determines if you will end up with a perfect or mediocre design. It also makes the difference between cutting down on waste or increasing material costs significantly. The bit is used to extract material in a specific way. Originally, routers used to be handheld tools that were guided by templates or ball-bearing pilots and they were moved manually around the workpiece. Nowadays, routers are controlled using computers that accurately determine the toolpath, and these routers require bits to make intricate cuts.

FROGTools™: Specialized Router Tools For All Your Foam-Cutting Needs

The variety of materials and designs cut by router bits has grown noticeably in diversity, and as a result, so have the types of CNC router bits. In today’s market, it is not unusual to find so many router bits that picking the right bit for a project requires research instead of making an intuitive decision. As well, adapting your feeds, tooling and speeds per application is absolutely crucial to getting the best out of your investment. Since each material differs in texture, thickness, and usability, tooling and machine settings must reflect what you are trying to achieve. As a result, selecting the right tool for the job can make all the difference between a perfectly smooth and clean cut, or something that looks like it has been roughly hacked out with an axe! In the worst cases, a wrong tool can simply split or break before even any cutting has been done. When we talk about router bit varieties, we’re really only talking about the cutting edge of the bit as that is the most important part of a bit that will help to shape your final product.

FROGTools™ are durable and made specifically for milling EPS and polyurethane foam, including regular and tapered cutters in ball end and end mill styles. These tools are the only CNC foam tools that allow you to achieve depth and precision for foam carving applications. The standard FROGTools™ for foam comes in flat bottom and rounded bottom profiles.

- Tapered tools: This type of tool allows you to achieve high detail in deep cuts, and improves the intricacy and detail of your products. Longer bits allow deeper cuts and thicker slices with fewer passes, which means you spend less time in assembly work and will have fewer seams to cover after machining, and this in turn improves productivity. Props and sculptures also make great use of the round bottom bits, as they can follow an organic surface without gouging into your material.

Each standard FROGTool™ is titanium nitrate (TIN) coated to deliver the best in performance and durability, and is designed to last and save you the cost of recurring replacements that are typical of lesser quality tools. With up to 10 inches of cut length, these are the ultimate tool for foam milling as you can achieve larger parts in less time. In addition, all standard sizes for common milling processes are kept in stock and are available to ship immediately.

- Flat bottom tools: These are commonly used for sign-making and engineering-type parts as they generally consist of sharp corners and less organic surfaces than props or sculptures. Flat bottom drills are perfect for irregular surfaces because of their geometry and especially more if it’s required to achieve angular or tilted operations. Flat bottom tools are very useful for “roughing” work, as they can extract large amounts of materials per pass, and leave a flat uniform surface.

At FROG3D®, we taper our detail-cutting tools so that you can still achieve a deep cut without sacrificing tool rigidity. Less effective tools can produce chatter, substandard surface finishes, and unacceptable tolerances. Round bottom tools are not great for flat areas, since they require a smaller stepover to remove scallops and tooling lines, and this would take significantly more time to achieve the same surface quality that a flat bottom tool can.

FROGTools™ Sheet Goods: Router Tools For Alternative Materials

The FROGTools™ Sheet Goods package is a collection of tools for milling materials other than foam and comes in a few types such as Up-Cut, Down-Cut, and compression; this also includes a selection of cutters in ball end, end mill, and engraving styles. Some of the materials that FROGTools™ Sheet Goods can cut with its specialized cutting tools are wood, plywood, HDU, and plastics.

- Up-Cut: These tools are designed for solid and thicker materials like hardwood and MDF. Upcutting bits pull chips and material upwards, and are also great for making cuts through the material. When using upcutting bits, your material will need to be secured down and these specialized bits are recommended if you want to remove chips from your cuts to prevent overheating the bits. Flimsy sheets that are not fastened properly can be lifted off the table if the tool is overloaded and this can lead to a long list of potential problems.

- Down-Cut: Down-Cut tools function the opposite way and work well with thinner material. These tools push the chips down, and provide a clean upper surface of your material. Downcutting bits press the chips and material back into the cut, and this downward movement is great for preserving the top surface of your material. Down-Cut bits are useful for cutting thin and flexible material but are not the best for drilling holes as the bottom layer of the workpiece will be propelled away from the bit by chips. However, these tools can also clog up if you don’t have proper feed and speed settings, as the chips are packed down instead of being expelled out.

- Compression: Compression tools combine Up-Cut and Down-Cut geometries and offer the benefit of both bits. Compression bits provide a clean surface on both the top and bottom of your sheet, but are usually only appropriate for through cuts instead of pocket-type cutting. This type of bit is very useful for cutting laminated materials. When cutting materials like plywood, for instance, a compression bit will give you a clean edge on both sides because the top is pushed down while the bottom is pulled up. Combining both geometries resists chipping and reduces the risk of damaging the workpiece. Compression bits are recommended for laminates, composites, and plywood.

Form Tools

A form tool is a specialized tool or machine accessory which is used to replicate the same shape multiple times on a workpiece surface. These tools are often a special order choice among machine shops due to the advantages they offer such as accuracy, cycle time, and finish; this makes form tools a cost-effective pick for machining complex profiles. This type of tooling is also more accurate than standard tooling because a turning tool involves two machine axes whereas a form tool uses only one machine axis. Fewer moving parts contribute to less error, which allows achieving tight tolerances easier. Another benefit of using form tools is the finish. When using a single-point tool, there will be cusps between rotations of the material because the cutting edge travels along the contour. Using a form tool omits these cusps, since the entire component of the part characterized by the form is machined in a single plunge.

Form tools are essentially custom inserts, and the cutting edge matches the intended profile of the part. Due to this, a single straight plunge with the insert produces the needed shape. Form tools are common in the cabinetry industries and are found on edging routers, where milling operations are more comparable to plunge-routing processes. A plunge base router is designed so that you can predetermine the cut depth and then lower the bit into the cut with the router’s base flat on the surface material. These routers work like fixed-base routers in that they have high-speed motors, use the same bits, and mill the desired material to shape and size. Bearing bits should never be used on an automated router system. This bit is good for trim routing by hand, where the bearing runs on the edge like a guide and maintains the distance of the blade to the material. In automated routers, the machined path is maintained by mechanical parts and the program is the guide.

That being said, a form tool is anything other than a straight tool, and our tapered FROGTools™ can be considered form tools as the cutting edges are not parallel to the Z-axis motion. Form tools like engraving tools are common in many industries and are suitable for text work, beveling edges, and other fine details. They are commonly available in 90 and 60 pitches, but can be sourced in unlimited geometries. However, engraving tools are not suitable for removing large amounts of material, as the tip of the tool tapers to what is essentially 0 wide, and this would likely be an extremely slow process and would leave a rough surface.

FROG3D® has the experience, innovation, and out-of-this-world support services to make sure you receive the best tools and equipment for your next project! We work with our clients to take their businesses, production processes, and products to new levels- we measure our success by how successful our clients are! We handle every feature of the customer experience in-house including product demonstration, installation, training, and support to provide reliable equipment solutions. Our comprehensive approach is as unique as the companies we work with, and this translates to exceptional business growth for our clients. Contact us today to learn more about selecting the right tooling options and best speeds that will ensure your complete satisfaction.