Automation in the Construction Industry

The construction industry is an evolving and fast-paced field that requires a high level of precision and attention to detail. Human errors can result in costly mistakes, delays in project advancement, and even injuries. Implementing automated processes for construction-related products and tasks can help companies to reduce errors and increase efficiency by automating time-consuming tasks. These processes allow for higher production rates, increased productivity, efficient use of materials, better product quality and improved safety for workers.

The scope of automation in construction is broad as it incorporates all the stages of product development from initial planning and design to engineering and manufacturing of the products. The FROGBase™ is a powerful mold-making engine that integrates the craftsmanship of standard processes with the efficiency of automation. It is a proprietary software package that was developed for the concrete industry, and designed to build molds for precast concrete drainage products such as pipes, manholes, and catch basins. The traditional processes used to create pre-bench molds require a lot of time and effort and are generally inflexible.

As the industry advances, there is a shift to move toward more automated processes. Traditional and manual work practices are gradually being replaced as new users are taught how to use the equipment and software that supports the new changes in the industry. Streamline Automation can help you integrate state-of-the-art automated production capabilities, facilitate repeatability, and accelerate production tasks.

What are Manholes?

Manholes are vertical and small underground spaces used by utility personnel as a point of access to a sewer system. Sewer systems are built underground with pipes that transport waste from homes and buildings to a place of treatment or waste disposal. To maintain a sewer system, it is necessary to perform frequent inspections, cleaning and repairs. Utility personnel and crews utilize manholes to get closer access to pipes or other parts of the underground system to accomplish these tasks. Manholes were initially built to provide specialized workers access to pipes and other underground materials but nowadays they are more so used for equipment. Crews lower their inspection cameras into manholes to retrieve CCTV footage and other equipment for cleaning or maintenance.

Manholes are designed with a cover lid and are made of grade adjusting rings, a top tapered section called the cone, the main cylinder section called the barrel, and a bench and a channel from where the waste can flow through.

The Three Main Types of Manholes

- Plastic: Plastic manholes are made by using polyethylene material. This is manufactured with durable one-piece construction. This construction does not utilize any seams or seals as they can cause various maintenance issues.

- Precast Concrete: The construction of manholes with precast concrete is a long-established method. Precast concrete manhole frames are manufactured in a factory located offsite and ensure quality as well as facilitate a quick installation. The engineered precast manholes are assembled on the site.

- Fiberglass: Fiberglass manholes are easy to manage and weigh one-tenth of the weight of the concrete manhole. Since the unit is lightweight, the manhole is easy to install. Fiberglass manholes are also environmentally friendly and highly durable.

Before the emergence of precast concrete manholes, the access point for sewer systems was made using brick and mortar. Masons built the structure in place which was time-consuming and took a lot of effort. With the advent of precast concrete manholes, the structure is engineered and built offsite at a controlled facility and transported to the construction site. The fully assembled manhole is lowered into its place and then connected to the pipes in the system, which is then backfilled with dirt. The process of producing manholes used to take days but thanks to automation this can now be completed in a matter of just a few hours.

Precast Molds

Precast concrete manholes are the construction industry’s product of choice instead of other non-concrete products for many reasons. Precast concrete manholes can be easily installed and immediately backfilled, and there is no requirement to wait for concrete or mortar to cure at the job site. Additionally, contractors are accustomed with how to handle precast concrete manholes and can install them easily. Products for water tightness such as standard sealants and flexible joints are also readily available.

Precast concrete is produced by casting concrete in a mold which is cured in a controlled environment, transported to the construction site, and then guided into its place. Machining processes vary from each industry to another but they generally follow the same principle when creating precast molds and prototypes. An initial drawing is provided and a prototype is made for a precast mold. After this, the design follows a preset number of machining steps on a versatile material such as foam, and then the mold is completed and is available for use in precast concrete manholes.

Usually, a precast mold is made for ease of installation and the time and energy savings that it brings. Without molds, concrete would be shapeless. Concrete has been making a substantial impact on design choices for many industries, notably within the construction industry given the manufacturing of manholes, catch basins, and pipes. The companies that pour concrete mixes into precise molds need a material that can be precisely shaped.

Well-made molds are essential in order to boost efficiency and reduce the amount of material that is used and discarded. Foam is a versatile and commonly used material for precast mold production and is fairly dense yet can be easily cut, sanded, routed, and shaped. Using EPS foam molds for concrete is an excellent choice as it allows the versatility for both CNC machine shaping and hand finishing of the mold. It is a superior material to use for custom-made molds and can be easily facilitated by FROG3D®’s CNC machines such as the FROGWire™ and FROGMill™.

Using automated equipment is cost-effective and efficient where automated workflows enable maximum productivity and offer unparalleled precision to facilitate your projects. Precast is one of the fastest-growing segments of the construction industry and FROG3D® offers state-of-the-art and unique workflows for the design, detailing, and implementation of precast products.

FROGWire™ and FROGMill™: FROG3D® CNC Machining Components

Computer Numerical Control (CNC) machining is a fabricating process in which pre-programmed computer software commands the movement of factory tools and machinery. Three-dimensional cutting tasks can be carried out in a single set of prompts when CNC machining is activated. CNC machining makes it possible to program the speed and position of machine tool functions and then run them through software in repetitive and predictable cycles. In this machining process, a 2D or 3D design is created after which the design is translated into computer code for the CNC system to deliver. When a CNC machine is activated, the desired incisions are programmed into the software and this follows the corresponding tools and machinery which carry out the geometric and structural tasks.

FROGWire™

The FROGWire™ is an essential tool to help you prepare materials before processing on the FROGMill™. The FROGWire™ works in conjunction with the FROGMill™ by preparing materials such as foam for milling in-house instead of paying to have the materials pre-slabbed or shaped.

The hotwire cutting system is elevated to multi-wire and multi-axis setups. These features bring tremendous benefits to the user and the production. When the number of hot wires increases, the production time decreases. Thanks to the multi-wire system of the FROGWire™, cutting functions can be replicated to run simultaneously on the same machine. Slabbing functions are usually used when multi-wire systems are utilized, where a single pass of hot wire is used to cut through many slabs to adjust for dimensions. The FROGWire™ can prepare your blocks and billets for milling, and provides many other useful functions such as slabbing, creating plugs, tapered molds, and much more.

FROGMill™

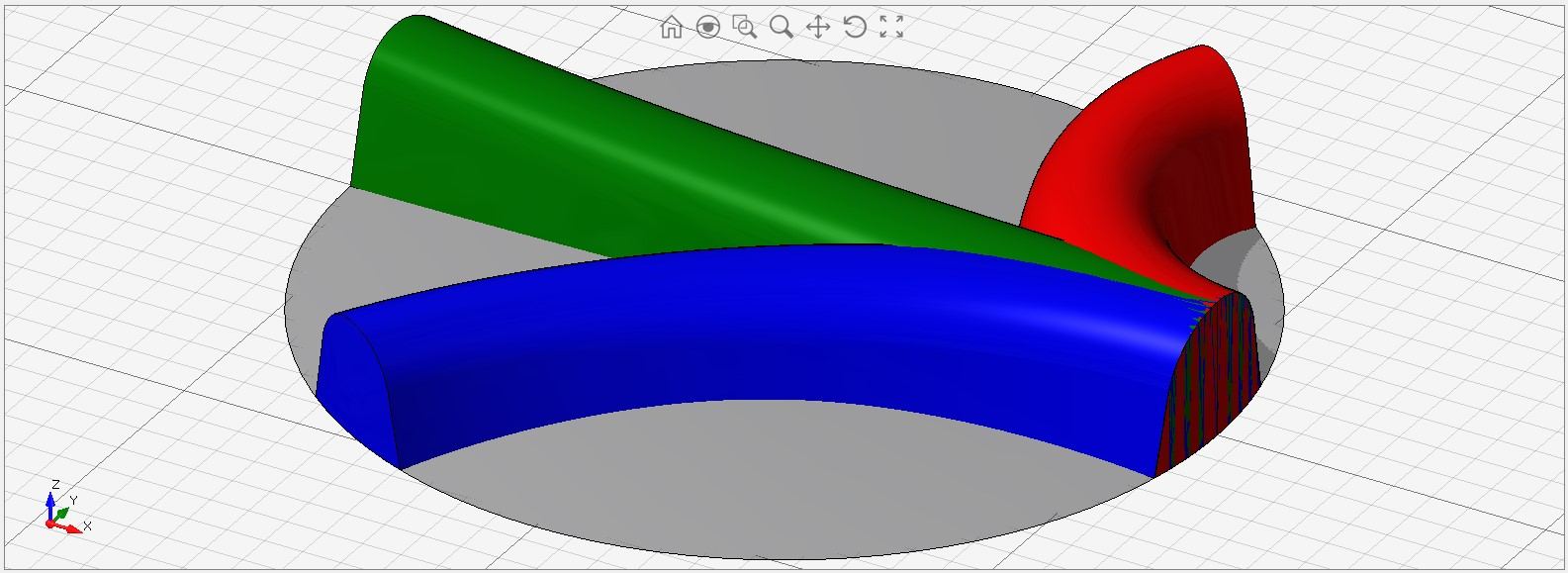

This is FROG3D®’s CNC milling machine which includes software and a dust collection setup. This machine is built to handle large-scale projects and professional industrial production lines, and is designed for larger process areas to deliver larger 3D jobs quickly and efficiently. The FROGMill™ utilizes large tools to efficiently complete the pre-bench molds, and based on your preference, they are created in a single piece with sweeping channels on seams on a sloped base.

In general, typical production steps for automated processes require several proprietary materials and steps- some even require a UV booth for hardening the surface coating. This can be time-consuming and you need a clean workspace, power, and staff. FROG3D® equipment provides more of a free-form solution and does not commit you to follow any specific processes. We offer software for producing pre-benches and systems that are great at machining foam rapidly.

How Does FROGBase™ Help With Manhole Production?

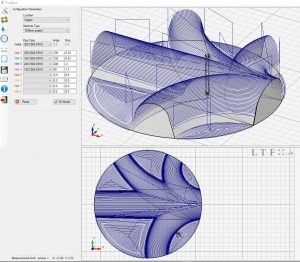

CAD/CAM is an acronym that stands for computer-aided design and computer-aided manufacturing software. This software is used to design and manufacture prototypes, finished products, and production runs of products. CAD/CAM applications are used to design a product as well as program manufacturing processes such as CNC machining. CAM software utilizes the models and assemblies created in CAD software such as FROGBase™ to generate toolpaths that instruct machine tools to turn designs into physical parts.

To create molds for precast concrete drainage products such as manholes, the FROGBase™ software can be used to design a 3D model of the mold after which the software would generate toolpaths that drive machine tools to create a final product for use in the concrete industry.

The FROGBase™ software produces the 3D geometry for your pre-benches and provides the tooling time estimates for scheduling purposes. This significantly reduces wasted time and gives you an optimized and efficient plan for toolpath generation within the same CAD/CAM package. The software also stores and loads pipe sizes, tool specifications, and base geometry for quick and reliable 3D model creation. The clean and simple user interface of FROGBase™ requires very little experience in CAD/CAM software.

Additionally, the automation systems work without the need for code generated from FROGBase™ Prebench software. This feature allows you to diversify your product lines- for instance, if you wanted to cut a sign or mill out a desk organizer, the system is more than ready to perform that task for you.

Oftentimes, typical automated manhole systems get into the real weeds of your business and require that you modify a significant portion of your admin processes in order to apply their automation. The FROG3D® solution on the other hand could be considered a stand-alone application, which means that you are able to ease into the automated processes without any slowdown or take breaks for your existing processes. This allows you to accelerate production, advance repeatability, and integrate state-of-the-art automated production capabilities.

FROGBase™ software stores all of your specific data in a separate file that can be edited by the user. This means that anything that is stored in the database is arranged and displayed in easy-to-read drop-down menus in the user interface, and can be customized to integrate with your current production processes.

With over 20 years of involvement in helping our clients to build their processes and businesses, we at Streamline Automation are well aware of the competitive 3D fabrication market inside and out. Our industry experts have unparalleled knowledge and hands-on experience in all aspects of the design, manufacturing and production processes. We offer our clients in-depth process training and guide them through the safe use and operation of our machines. It can be intimidating to incorporate automation and CAD software when you are used to fabricating all the steps manually, but our team at Streamline will ensure you ease into the process and guide you through our software step by step.

You do not need to purchase your materials and consumables from us – we don’t even sell foam, as a matter of fact! The experts at Streamline Automation are happy to guide you through any questions that you may have about the software and system information, processing steps and training- we will not mark up your consumables and take control of your admin processes. Contact us today!