Safety in any workplace should be the number one priority for both the employer and employee. Learning and knowing about the different hazards present when working around CNC machines should be the same as any other. Sharp spinning tools and flying debris are just some of the examples of hazards that could cause serious harm to an individual. At Streamline Automation, we take our safety measures very seriously and train our clients to do the same, for the sake of everyone who is involved in the project.

We have supplied catered systems for our clients in a variety of industries, and some of the facilities we’ve seen require custom safety solutions; anything from light curtains and security gates, to additional emergency stop stations further away from the machine. Although these additional measures can provide better-administered control, the most important safety device is knowledge.

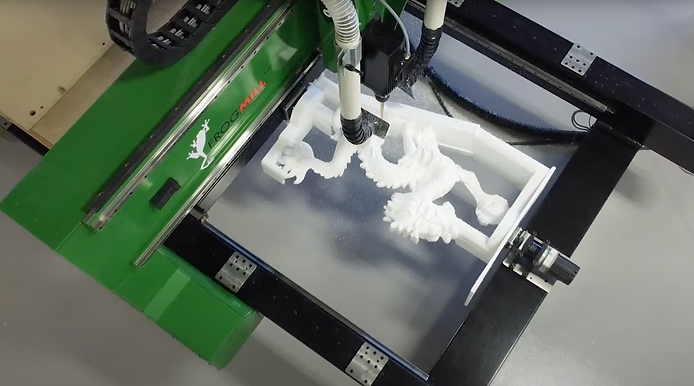

It has been our absolute pleasure to see the growth of our clients, and we pride ourselves to be able to help our clients deliver impactful technology that allows them to provide better, faster, and safer service. During equipment training, we stress the following major safety points to keep in mind when using any FROG3D® system:

Pinch Points

Be sure to keep your systems away from walls or posts. You should always, at any time, be able to walk safely around the entirety of the FROG system without the risk of the machine trapping the individual against an obstruction. This point is to help the people navigating around the machine to have enough clearance to load, unload, and adjust any materials around the system.

Tidiness

The FROG system should be kept free of debris all the time. Not only is a clean workspace beneficial for the accuracy and efficiency of production, but a clean workspace is a safe workspace!

Emergency Stops

Anyone within the vicinity of the FROG system during operation should know where the E-stops are. In the rare case the operator cannot reach the E-stop right away, any individual could be tasked with the important duty of shutting off the system in an emergency, whether or not they’re in charge of the operation.

Spatial Awareness

An automation system can suddenly change directions without warning. The quick speed of these systems is astounding, but it can be dangerous if staff members are not attentive near the machine. It is important for anybody in the area to be aware that the system is running and stay away from any moving parts at all times.

Overall, it’s critical to be aware of the environment, keep the workspace tidy, and ensure that all team members working with or near the machine are up to speed with all emergency procedures. These key points can also be found in our operator documents, so you can always refer back to them if you and your team need to brush up on your safety knowledge.

Streamline Automation is here to help answer any of your questions about CNC machining safety, so don’t hesitate to reach out to us. We can’t wait to work with you!