Home » Canadian-Made CNC Routers

Canadian-Made CNC Routers

Streamline Automation offers high-performance, Canadian-made CNC routers designed to meet the needs of businesses and manufacturers looking for quality, precision, and durability. Known for their accuracy, efficiency, and ability to handle a wide range of foam and alternative materials such as high-density urethane, acrylic, and wood, FROG3D® CNC routers are built to streamline production processes across industries. From custom manufacturing and prototyping to large-scale production and themed environments, FROG3D® CNC solutions provide reliable, high-quality results that enhance productivity and expand creative possibilities.

Our commitment to excellence in design and engineering means that each CNC router is optimized for industrial applications, bringing durability, advanced functionality, and user-friendly operation to every project.

FROGMill™

4-axis CNC foam carving router

Industry’s most versatile 4-axis CNC foam carving router, giving you capabilities impossible with traditional processes or standard machines.

FROGMill™ Lite

Compact 4-axis CNC router

Delivering a wide range of functionality at a compelling price-point.

What is a CNC Router and How Does It Work?

A CNC router is a computer-controlled machine designed for cutting, shaping, and carving materials like wood, plastic, and foam. It operates by following a programmed set of instructions that control the router’s movements, enabling precise, automated cutting and shaping with minimal manual intervention.

Why Choose FROG3D® Canadian-Made CNC Routers?

Superior Canadian Engineering and Quality

Manufactured in Canada, FROG3D® CNC routers embody superior craftsmanship and high standards of quality control. With precision engineering, robust construction, and advanced features, these routers are built to deliver long-lasting performance even in demanding production environments.

Designed for Versatile Applications

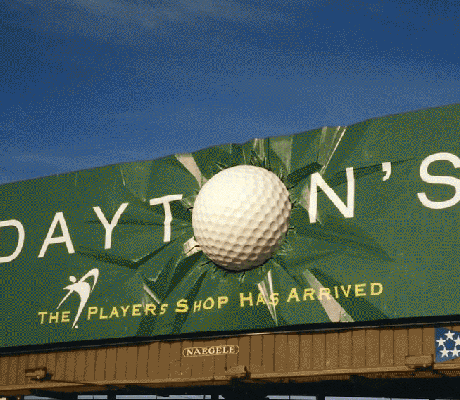

FROG3D® CNC routers are versatile machines capable of handling various materials such as foam, and wood, among others. From signage and billboards to props, precast concrete molds, architectural models, and more, FROG3D® CNC routers promote diverse applications across multiple industries.

Advanced Automation and Precision

Our CNC routers offer advanced automation and precise control, allowing for seamless integration into existing workflows. High-resolution cutting capabilities ensure that complex designs and intricate shapes are produced accurately, reducing material waste and optimizing output quality.

User-Friendly Operation

Designed with both experienced technicians and newcomers in mind, FROG3D® CNC routers come with intuitive software and easy-to-use controls. The streamlined user interface and customizability make it simple to set up and operate, ensuring smooth production processes for all types of projects.

Key Equipment: FROG3D® CNC Routers

FROG3D® CNC routers, including the FROGMILL™ and FROGMILL™ LITE, offer industry-leading technology and precision for large-scale cutting and fabrication.

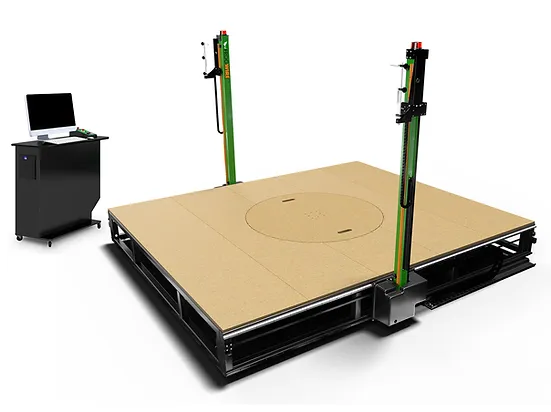

FROGMILL™

The FROGMILL™ is a powerful, 4-axis CNC router designed for complex and large-scale projects:

- High Precision: Capable of achieving detailed cuts and intricate shapes, ideal for high-end finishes.

- Efficiency and Speed: Increases productivity by automating complex cuts with rapid speed and exceptional accuracy.

- Versatility: Handles a variety of non-metal materials like foam and wood, suitable for applications from sculpture and props to architectural elements, and precast concrete.

Specifications

| Metric | Standard | |

| Overall Length: | 366 cm | 144.13″ |

| Overall Width: | 222 cm | 87.56″ |

| Overall Height: | 242 cm | 95.31″ |

| Weight: | 1134 kg | 2500lbs |

| Process Area L x W: | 315 cm x 162.5 cm | 124″ x 64″ |

| Under Gantry Clearance: | 40.6 cm | 16″ |

| Z-Axis Stroke: | 66 cm | 26″ |

| Maximum Cutting Speed: | 432 mm/s | 1000 IPM |

| Maximum Traverse Speed: | 508 mm/s | 1200 IPM |

| Accuracy: | 0.025 mm | 0.001″ |

| Repeatability: | +/-0.05mm | +/-0.002″ |

| Maximum Column Diameter: | 116 cm | 46″ |

| Maximum Column Length: | 252 cm | 99.5″ |

| Motors: | Servo Motors | |

| Motion: | Rack & Pinion on all axes | |

| Network: | TCP/IP, 10Base2 or 10BaseT | |

| Spindle Horsepower: | 5.5 hp with max 1″ collet size | |

| Electrical Specifications: | 208-240V, 30 Amp, 3 ph 50/60 Hz | |

Key Features

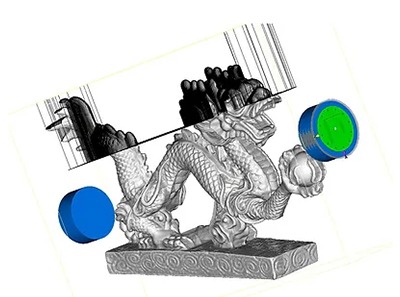

The FROGMill™ is the most versatile 4-axis CNC router available. Combined with industrial strength, unequalled quality and precision, the FROGMill™ provides you the capabilities you need to create larger and more intricate pieces.

The 4th axis offers index cutting capabilities to create full 3D carvings (up to a 4’ diameter and 8’ length) from a single piece. Mounting directly onto FROGMill™, the 4th axis rotational capabilities lets you go from ‘art to part’ in the shortest amount of time possible. The FROGMill™ 4-axis CNC router creates production efficiencies, but it also provides the accuracy and detail you need to create stunningly detailed projects.

FROGMILL™ LITE

FROGMILL™ LITE offers a compact, cost-effective solution with the same level of precision and functionality as the FROGMILL™:

- Compact Design: Perfect for smaller workspaces, providing the same high-quality results as larger CNC routers.

- Cost-Effective: Provides an affordable entry into automated CNC machining without compromising on performance.

- Flexible Applications: Handles foam, wood, and other lightweight materials for diverse applications, from prototyping to small-batch production.

Specifications

| Overall Length: | 121″ |

| Overall Width: | 73” |

| Overall Height: | 72” |

| Process Area (L x W): | 100”x 56” |

| Under Gantry Clearance: | 12” |

| Z-Axis Stroke: | 12.5” |

| Maximum Traverse Speed: | 800 IPM |

| Accuracy: | + 0.001 in |

| Repeatability: | + 0.002 in |

| Maximum Column Diameter: | 36” |

| Maximum Column Length: | 72” |

| Motors: | Servo |

| Motion: | Rack & Pinion on all Axes |

| Spindle Horsepower: | 5 hp with max 3/4” collet size |

| Electrical Specifications: | Single Phase Power (230 volt 30 Amp) |

Key Features

Perfect for fabricators and start-ups with moderate production needs, budgets or limited shop space and boasting the same exceptional quality, training and support that defines all FROG3D® products. Compact CNC router FROGMill™ Lite gives you the tools to drive production, expand capabilities, and grow your bottom line.

Optional 4th axis allows you to add functionality down the line, while a single-phase power supply makes FROGMill™ Lite easy to install in any space. Replace onerous manual processes with an automated solution, take on larger, more lucrative projects, and achieve stunning results with a solution that is designed to grow with your business.

FROG3D® Software: Seamless Integration and Control

Streamline Auomation’s FROG3D® line of products also offers a robust software suite tailored to simplify every stage of the production process. Our software includes CAD/CAM capabilities, enabling businesses to create, modify, and optimize digital designs for CNC machining.

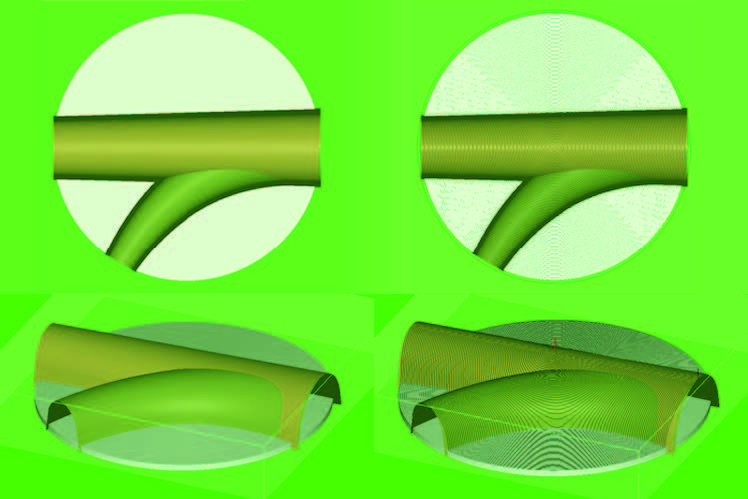

- 3D Model Design and Editing: Design complex shapes with intuitive tools that support intricate geometries.

- Automated Toolpath Generation: Automatically generates precise toolpaths, maximizing cutting efficiency and accuracy.

- Real-Time Monitoring: Track production in real-time, enabling quick adjustments and ensuring high-quality results.

Create 2,3 and 4-axis Hot Wire Cuts

A comprehensive software designed to easily create 2,3 and 4-axis cutting programs for the FROGWire™.

FROG3D® Training and Support

- Installation and Setup: Our team provides professional installation and setup to ensure your equipment operates at peak performance both remotely and in person.

- In-Depth Training Programs: We offer hands-on training sessions covering everything from basic operation to advanced software control, empowering your team to operate FROG3D® CNC routers effectively.

- Dedicated Technical Support: Our knowledgeable support team is available to answer questions, assist with troubleshooting, and offer guidance to keep your projects on track.

Applications of FROG3D® CNC Routers

FROG3D® CNC routers provide solutions for a wide range of applications:

- Signage and Billboards: Create detailed, large-scale signage that stands out with clean lines and intricate designs.

- Props and Themed Environments: Fabricate custom props and immersive environments with precision and scale.

- Architectural Models and Elements: Produce architectural features, models, and prototypes with accuracy and design flexibility.

- Sculptures and Art Installations: Bring artistic visions to life with intricate detailing and customizable finishes.

- Concrete and Building Materials: Discover computer-controlled machines for shaping materials with accuracy and consistency that sets new industry standards.

Industry Applications

Financing Available for FROG3D® Equipment!

Investing in advanced CNC technology is a significant step toward enhancing productivity, precision, and creative potential. To help businesses access the benefits of FROG3D® CNC routers, we offer flexible financing options tailored to suit different budget needs. Our financing plans allow you to acquire the equipment you need today while managing payments in a way that aligns with your cash flow and operational goals.

Benefits of Financing FROG3D® equipment:

- Affordable Monthly Payments: Spread out the cost of your CNC router over time, making it easier to budget and allocate resources.

- Quick Access to Equipment: Financing enables you to get started with FROG3D® technology right away, maximizing your production capabilities without delay.

- Tax Advantages: Depending on your location and tax regulations, financing may offer potential tax benefits, helping to reduce overall costs.

- Preserve Working Capital: Keep your cash reserves intact by financing your equipment, allowing you to invest in other areas of your business simultaneously.

Our team is here to help you explore financing options and find a plan that best meets your business’s needs. Contact us today to learn more about financing opportunities and start elevating your production process with FROG3D® CNC routers.

Related Products

Where Can You Buy FROG3D® Canadian-Made CNC Routers?

To purchase FROG3D® Canadian-made CNC routers, contact our dedicated sales team. We work closely with businesses to understand their unique production needs and recommend the best solutions. Our experts are ready to guide you through the buying process, ensuring you receive the right CNC router for your applications. Reach out today to learn more about how FROG3D® can support your business goals with advanced, Canadian-engineered CNC routers.

FAQs About Our Canadian-Made CNC Routers

FROG3D® CNC routers are designed to work with foam, wood, MDF, and other lightweight materials that do not require coolant, making them suitable for a range of applications.

The FROGMILL™ is a high-capacity 4-axis CNC router for complex, large-scale projects, while FROGMILL™ LITE offers similar capabilities in a more compact, cost-effective design.

Yes, FROG3D® CNC routers are engineered for precision, enabling them to produce intricate details and smooth finishes, ideal for artistic and professional applications.

FROG3D® routers come with CAD/CAM software designed for 3D modeling, editing, and toolpath optimization, offering a complete solution for managing your CNC projects.

Yes, FROG3D® provides comprehensive training, including installation, hands-on operation, and advanced software usage, to ensure your team is fully equipped to operate the machines.

While FROG3D® routers are ideal for producing foam and wood signage or props, we recommend applying FROGSkin™ by Graco coatings for added durability in outdoor environments.

Industries such as architecture, art, signage, themed attractions, and manufacturing benefit from FROG3D® CNC routers due to their versatility, precision, and high-quality results.

To purchase a FROG3D® CNC router, contact our sales team for personalized assistance. We’ll work with you to assess your needs and recommend the best equipment for your applications.