Home » Coating Solutions

Coating Solutions

FROG3D® offers advanced coating solutions that provide durability, weather resistance, and aesthetic finishes for foam-based projects. Whether you’re creating sculptures, signage, architectural elements, or props, FROG3D®’s coating systems, FROGSkin™ by Graco and FROGCoat™, are designed to meet the specific needs of businesses and manufacturers working with foam. These solutions not only protect your projects from environmental damage but also deliver high-quality finishes that enhance both functionality and appearance.

With FROG3D®’s coating technologies, businesses can streamline production, improve product longevity, and achieve the precise look and performance required for a wide range of industries.

FROGskin™

BY

Plural component coating system

Electric spray system for applying polyurea and other coatings. Perfect solution for durable, smooth, or textured finishes.

FROGcoat™

Coatings and related materials

Complete line of coatings and related materials for sculptural, architectural and mold making applications that use foam as their foundation.

What Are Coating Solutions?

Coating solutions refer to protective layers applied to the surface of foam-based creations to improve durability, weather resistance, and aesthetics. These coatings act as a shield, safeguarding the foam structure from environmental factors like moisture, UV rays, and physical damage, while also providing a smooth or textured finish that enhances the visual appeal of the final product.

In foam-based installations—such as sculptures, signage, architectural features, and themed environments—coating solutions are essential for several reasons:

- Durability: Foam, while versatile and lightweight, is prone to wear and tear, especially in outdoor or high-traffic environments. Coatings like FROGSkin™ and FROGCoat™ protect the foam by creating a durable outer layer that can withstand impact, abrasion, and harsh weather conditions.

- Weather Resistance: For outdoor installations, exposure to elements like rain, sunlight, and humidity can degrade foam over time. Coating solutions provide a protective barrier against moisture and UV damage, ensuring that the structure retains its strength and appearance for longer periods.

- Aesthetic Enhancement: Coatings not only protect but also improve the look of foam-based installations. Whether you’re aiming for a sleek, polished surface or a textured, artistic finish, coatings offer flexibility in achieving the desired visual effect. They allow for custom colors and finishes, transforming raw foam into visually stunning works of art or functional structures.

- Longevity: By applying the right coating, you significantly extend the lifespan of your foam-based project. This reduces the need for frequent repairs or replacements, saving time and costs for businesses and manufacturers in the long run.

Coating solutions are vital for foam-based installations, ensuring that the final product is not only aesthetically pleasing but also robust enough to withstand environmental and physical challenges. Whether you’re working on architectural pieces, sculptures, or large signage, a high-quality coating ensures your project endures the test of time.

FROGSkin™ by Graco: Plural Component Coating System

FROGSkin™ is an industry-leading coating solution designed specifically for foam applications. Engineered to provide a tough, durable outer layer, FROGSkin™ delivers exceptional protection against weather, wear, and impact.

- Durability: Protects foam-based creations from external elements such as moisture, UV rays, and physical damage.

- Flexible Application: Suitable for various foam-based projects including large sculptures, signage, architectural elements, and themed environments.

- Customizable Finishes: FROGSkin™ can be applied with different textures and colors, allowing you to achieve the perfect aesthetic for your project.

Specifications

| Specification | U.S. | Metric |

|---|---|---|

| Maximum Fluid Working Pressure | 3000 psi | 207 bar 20.7 MPa |

| Maximum Fluid Temperature | 180 °F | 82.2 °C |

| Maximum Flow Rate | 2 gpm | 7.6 lpm |

| Maximum Heated hose Length | 220 ft | 67 m |

| Approximate Output per cycle (A+B) | 0.0104 gal | 39.4 cc |

| Operating Ambient Temperature Range | 20 °F to 120 °F | –7 °C to 49 °C |

| Fluid Inlets | 3/4 npt(f) | |

| Fluid Outlet – A | #8 (1/2 in.) JIC with #5 (5/16 in.) JIC adapter | |

| Fluid Outlet – B | #10 (5/8 in.) JIC with #6 (3/8 in.) JIC adapter | |

| Fluid Circulation Port Size | 1/4 nps(m) | |

| Fluid Circulation Port Maximum Pressure | 250 psi | 17 bar 1.7 MPa |

| Standard Models | ||

| Maximum Fluid Inlet Pressure | 400 psi | 27.6 bar 2.76 MPa |

| Pro and Elite Models | ||

| Maximum Fluid Inlet Pressure | 600 psi | 41.4 bar 4.14 MPa |

| Line Voltage Requirements | ||

| 200–240 VAC 1–ph 50/60 Hz | ||

| 200–240 VAC 3–ph DELTA 50/60 Hz | ||

| 350–415 VAC 3–ph WYE 50/60 Hz | ||

Sound Pressure Measured per ISO-9614–2 Measured from 3.1 ft (1 m) @ 3000 psi (21 MPa 207 bar) 1 gpm (11.4 lpm) | 85.1 dBA | |

Sound Power Measured from 3.1 ft (1 m) @ 3000 psi (21 MPa 207 bar) 1 gpm (11.4 lpm) | 92.15 dBA | |

| Dimensions | ||

| Width | 24.9 in. | 63 cm |

| Depth | 15.0 in. | 38 cm |

| Height | 56.5 in. | 144 cm |

| Weight | ||

| Elite 10 kW | 270 lb | 122.5 kg |

| Wetted Parts | ||

| Material | Aluminum, stainless steel, zinc-plated carbon steel, nickel-plated carbon steel, brass, tungsten carbide, chrome, chemically resistant o-rings, PTFE, acetal, ultra high molecular weight polyethylene | |

Key Features

Thanks to unique mixing, pumping and dispensing technologies, FROGSkin™ by Graco is the perfect solution for applying durable smooth or textured finishes to your architectural, sculptural or themed pieces, negative cavity molds, etc.

Together with Streamline’s FROGCoat™ line of coatings, FROGSkin™ by Graco is the ultimate coating solution for a wide range of applications.

FROGCoat™: Coatings and Related Materials

FROGCoat™ offers a high-performance coating solution for finishing foam-based creations, with an emphasis on delivering a polished and professional appearance.

- Smooth and Even Coverage: Provides a flawless finish that enhances the visual quality of foam structures.

- Protection and Longevity: Extends the life of foam projects by shielding them from environmental factors such as temperature fluctuations, moisture, and UV exposure.

- Versatility: Ideal for applications across various industries, from architectural facades to props and displays, ensuring your project looks its best and withstands the test of time.

Specialized Coatings

FROGCoat™ Coatings give you proven coating products for your artistic applications. There’s no sorting through hundreds of irrelevant products or working with coatings (or suppliers) not built for your needs. Whether you need spray coatings, in-mold coatings or mold making materials, FROGCoat™ delivers the right coating for your project.

One Stop Shopping

With Streamline, you get all of the equipment and coatings you need to build your competitive advantage, without the runaround that comes with multiple suppliers. Rather than trying to create a piecemeal solution, our equipment and coatings have been designed and tested together, so you get a solution that works – from start to finish.

Expertise and Experience

FROGCoat™ Coatings are backed by a team with real world expertise and hands-on experience, both with the coatings we offer and with the kinds of projects our clients produce. We support businesses around the world in these applications, so we understand how our products can work for you.

Training and Support

Comprehensive Training and Technical Support – FROG3D® products are backed with second-to-none training programs and technical support to get you up and running quickly.

Why Choose FROG3D® Coating Solutions?

FROG3D® coating systems are engineered to address the unique needs of foam-based manufacturing, providing tailored solutions that elevate your project both aesthetically and functionally. By applying FROGSkin™ or FROGCoat™, you can ensure your foam creations are not only protected but also finished to the highest professional standards.

- Protection: FROG3D® coatings deliver long-lasting protection, minimizing maintenance and extending product life.

- Quality: Achieve impeccable finishes with customizable textures and colors to match your project’s design vision.

- Efficiency: Our coating systems are easy to apply, saving you time and labor in the production process.

Industries and Applications for FROG3D® Coating Solutions

FROG3D® coating solutions are versatile and can be used across a variety of industries, enhancing the durability and appearance of foam-based creations. Some common applications include:

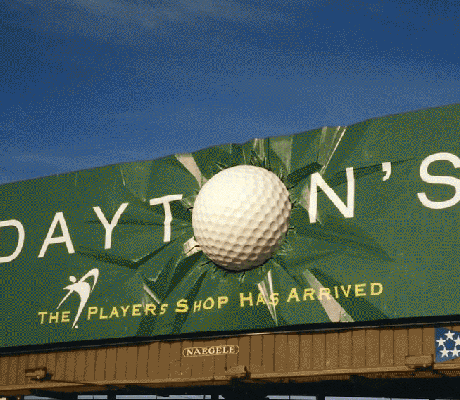

- Themed Environments and Attractions: Create durable, weather-resistant props and set pieces for theme parks, exhibitions, and events.

- Sculpture and Art Installations: Protect large-scale sculptures from the elements while achieving a high-quality aesthetic finish.

- Signage and Displays: Add durability to outdoor signage, ensuring it withstands weather conditions while maintaining a vibrant, professional look.

- Architectural Features: Coat architectural elements such as façades, columns, and decorative features to protect them from environmental wear and ensure long-term stability.

Industry Applications

FROG3D® Software

FROG3D®’s coating systems integrate seamlessly with our full suite of CNC and fabrication technologies. Paired with advanced CAD/CAM software, you can plan, design, and execute complex projects with precision. The software not only assists in creating the original 3D models but also in determining the exact amount of coating required for each project, optimizing material usage, and ensuring a flawless finish.

FROG3D® Training and Support

To ensure you get the most out of FROG3D®’s coating solutions, we offer comprehensive training and technical support. Our team will provide hands-on training to ensure your staff is fully equipped to apply coatings efficiently and effectively, maximizing the quality and longevity of your foam projects.

- Installation and Setup: We assist with the installation of your coating system, ensuring it’s configured for optimal performance.

- Ongoing Support: Our team is available for technical support and troubleshooting, ensuring that you maintain a smooth workflow and achieve consistent results.

To learn more about how Streamline Automation can help you increase production and expand manufacturing capabilities, contact us or explore our work samples here.

Related Products

Where Can You Buy FROG3D® Coating Solutions?

FAQs about Coating Solutions

Coating solutions are beneficial for a wide range of foam-based projects, including:

- Sculptures and art installations

- Architectural features and decorative elements

- Outdoor signage and displays

- Props and themed environments for attractions

- Stage sets and exhibition structure

In each case, coatings help protect the foam while enhancing the appearance and durability of the project.

FROGSkin™ by Graco is a more robust coating solution designed to provide heavy-duty protection for foam structures. It offers exceptional durability, impact resistance, and weatherproofing for large-scale, outdoor, or high-traffic installations.

FROGCoat™, on the other hand, focuses on delivering a smooth, polished finish with excellent coverage. It is ideal for projects where a flawless, professional appearance is essential, while still protecting environmental elements.