Large-format 3D printers are revolutionizing industries that require the production of oversized, intricate designs. Unlike standard 3D printers, these machines are designed to handle large-scale projects with greater precision and speed. They allow businesses to create massive objects in a single print, whether it’s architectural models, construction components, or artistic installations. The ability to print at a larger scale means reduced assembly time, lower production costs, and the opportunity to fabricate complex designs that would be impossible with traditional methods.

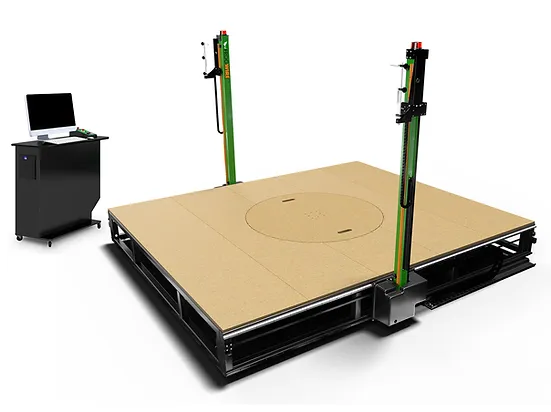

Large-scale 3D printers also offer significant versatility in material usage. This makes them ideal for a range of applications, from prototyping to full-scale manufacturing. One such innovative solution is FROGPRINT™ by Nexum, which combines size, accuracy, and flexibility, allowing companies to efficiently produce high-quality, large-scale structures without compromising on detail.

Equipment

FROG3D® brings advanced 3D fabrication capabilities to your production challenges. Creative, adaptive, exceptional, our turnkey 3D CNC fabrication system gives you the tools to work bigger, better, and faster. With cutting-edge technology, commercial-grade construction and industry leading training and support, FROG3D® bridges the gap between your creative process and production needs.

What is 3D Printing?

3D printing, also known as additive manufacturing (AM), is an innovative technology used to create three-dimensional objects by building them layer by layer. Unlike traditional manufacturing methods that involve cutting or subtracting material from a solid block (subtractive manufacturing), 3D printing adds material in successive layers to form the desired shape.

Most 3D printers commonly use plastic polymers like foam, wood, MDF, plastics, and other lightweight materials to create objects. This versatility makes 3D printing suitable for a wide range of industries, from prototyping to large-scale production.

The technology’s flexibility allows for intricate geometries and complex designs that would be difficult or impossible to achieve with traditional manufacturing methods. From rapid prototyping and custom product development to small-batch manufacturing and artistic applications, large-format 3D printers have transformed industries by offering greater design freedom, faster production times, and reduced material waste.

FROGPRINT by Nexum: Revolution in Large-Scale 3D Printers

Specifications

| Machine Properties | NX3500 | NX3000 | NX2300 |

| Build width | 1000 mm diameter (39.4″) | 1000 mm diameter (39.4″) | 1000 mm diameter (39.4″) |

| Build height | 2000 mm (82.6″) | 1500 mm (61.0″) | 900 mm (36.2″) |

| Travelspeed | up to 600 mm/s | up to 600 mm/s | up to 600 mm/s |

| XYZ resolution | 20, 20, 50 micron | 20, 20, 50 micron | 20, 20, 50 micron |

| Layer Resolution | |||

| 0.4 mm nozzle | 300 – 50 micron | 300 – 50 micron | 300 – 50 micron |

| 0.6 mm nozzle | 400 – 50 micron | 400 – 50 micron | 400 – 50 micron |

| 0.8 mm nozzle | 600 – 50 micron | 600 – 50 micron | 600 – 50 micron |

| 1.0 mm nozzle | 800 – 50 micron | 800 – 50 micron | 800 – 50 micron |

| 1.2 mm nozzle | 1000 – 50 micron | 1000 – 50 micron | 1000 – 50 micron |

| 1.4 mm nozzle | 1200 – 50 micron | 1200 – 50 micron | 1200 – 50 micron |

| 1.8 mm nozzle | 1400 – 50 micron | 1400 – 50 micron | 1400 – 50 micron |

| Physical dimensions | |||

| Dimensions | 1350 mm x 1600 mm x 3550 mm | 1350 mm x 1600 mm x 3050 mm | 1350 mm x 1600 mm x 2350 mm |

| Net. weight | 375 kg | 275 kg | 245 kg |

| Heated build plate | |||

| Build plate temperature | up to 110 °C (230 ºF) | up to 110 °C (230 ºF) | up to 110 °C (230 ºF) |

| Build plate levelling | Automatic | Automatic | Automatic |

| Heat up time (up to 60 °C) | < 7 min | < 7 min | < 7 min |

| Print head | |||

| Nozzle temperature | up to 500 °C (932 ºF) | up to 500 °C (932 ºF) | up to 500 °C (932 ºF) |

| Nozzle heat up time | < 90 sec | < 90 sec | < 90 sec |

| Max. extrusion volume | Up to 135 mm³/s | Up to 135 mm³/s | Up to 135 mm³/s |

Key Features

Excelling at high detail elements, when integrated with the FROG3D® System, FROGPrint™ by Nexum scales up productivity by tackling key features and running concurrently to other FROG3D® System components.

Combined with a compatibility with over 20 different print materials and easy turnkey functionality, FROGPrint™ by Nexum provides the freedom and flexibility to take on any project and crush it.

Note: FROGPrint™ by Nexum large volume printers cannot print PEEK filament. If printing PEEK filament, contact us for alternative models.

3 Steps of Creating 3D Objects with Large Scale 3D Printer

1. Design

The creation of a 3D-printed object starts with a digital model, typically made using computer-aided design (CAD) software. Skilled designers and engineers use CAD to develop entirely new designs or digitally capture real-world objects using 3D scanners. Increasingly, automated design processes are being implemented with the help of artificial intelligence and parametric design software, which enables more efficient and complex design generation.

2. 3D Print

Before printing can begin, the CAD model must be converted into individual layers. This is done using slicing software, or “slicers.” The slicer breaks the digital model into thin layers and generates G-code, a machine language used in computer-aided manufacturing (CAM). G-code directs the 3D printer’s movements, controlling how it builds the object layer by layer, transforming the digital model into a physical reality.

3. Post-Processing

Once the object is printed, post-processing may be necessary to refine and enhance the final product. Post-processing includes any steps taken after printing to improve the quality of the object, such as removing supports, sanding, painting, or applying coatings. These finishing touches help perfect the appearance and functionality of the 3D-printed object, ensuring it meets the desired specifications.

Key Benefits of Large-Format 3D Printer from FROG3D®

3D printing provides significant advantages over traditional manufacturing methods, offering businesses remarkable efficiency in production. As this disruptive technology evolves, with constant advancements in 3D printing techniques and the development of stronger, more versatile polymer materials, its range of applications is rapidly expanding. Companies investing in 3D printing benefit from enhanced speed, flexibility, cost savings, and environmentally friendly practices.

Speed

3D printing allows for the rapid creation of complex, geometrically intricate objects, often within hours, depending on size. Traditional manufacturing methods are infamous for their long lead times, which can delay production for weeks. In contrast, 3D printers operate as highly reliable, unattended systems capable of producing full-scale objects overnight, allowing businesses to have parts or products ready the next day without disruption to workflows.

Flexibility

Unlike traditional methods that rely on physical tooling, patterns, or molds, large 3D printers use digital files such as CAD models, offering unparalleled flexibility. This digital approach significantly benefits small-scale production runs or fully customized designs, as it eliminates the need for manual tooling and allows for rapid iterations. The ability to easily modify designs without the need for new molds or setups makes 3D printing an ideal solution for prototypes, custom orders, or short-run production.

Cost

Three key factors impact manufacturing costs: materials, operational expenses, and labor. 3D printing stands out by using an additive process, where only the required material is used to create the object, minimizing waste compared to traditional subtractive methods. Additionally, because 3D printing is an automated, single-step process, labor and operating costs are significantly reduced, allowing staff to focus on other tasks. Manufacturers also save money on tooling costs, as large-scale 3D printers don’t require specialized molds or equipment to accommodate design changes.

Applications of Large 3D Printers

Large-format 3D printers are used in various applications, including:

Industry Applications

How to Choose a Large-Scale 3D Printer?

When selecting a large 3D printer, it’s important to consider several key factors to ensure the printer meets your production needs:

- Build Volume: The primary advantage of large-scale 3D printers is their capacity to print oversized objects. Evaluate the maximum build volume based on the size of the parts or models you need to create.

- Material Compatibility: Consider the materials you’ll be using. Some printers are designed to handle specific types, such as plastics, resins, or composites. Make sure the printer supports the materials required for your applications.

- Print Resolution and Precision: High resolution is crucial for detailed and intricate designs. Look for a printer that offers fine layer heights and precise control for smooth surfaces and accurate dimensions.

- Print Speed: Large-scale projects can take time, so selecting a printer with a good balance of speed and quality is essential, especially for meeting tight deadlines or large production runs.

- Ease of Use and Software Integration: Ensure the printer is compatible with your existing CAD software and has user-friendly controls. Advanced slicing software should also provide options for optimizing your prints.

- Post-Processing Requirements: Depending on the printer and material, some models may require more post-processing, such as support removal or surface finishing. Choose a printer that aligns with your production workflow.

- Maintenance and Support: Large-format 3D printers often require regular maintenance. Choose FROG3D® to get reliable technical support, training, and easy access to replacement parts.

Considering these factors will help you choose the right large-scale 3D printer that fits your production requirements, optimizes costs, and ensures high-quality output.

FROG3D® Training and Support

At Streamline Automation, we are dedicated to setting our clients up for success. Our work spans various roles, industries, and applications, allowing us to meet your most pressing business and personal needs. We look forward to helping you achieve your business goals and are excited to collaborate. The custom fabrication market is highly competitive, and we have the expertise to help you overcome upcoming challenges.

Whether you’re a hobbyist or a professional, Streamline Automation offers extensive training programs in custom fabrication. With almost 25 years of experience, our industry experts provide unparalleled knowledge and hands-on experience, ensuring you have everything you need to bring your ideas to life.

In addition to safe operation training for our FROG3D® machines, we offer in-depth process training to help you create your projects. Our comprehensive training regimen makes the FROG3D® fabrication system ideal for companies starting with CNC machinery, or seasoned users.

To learn more about how Streamline Automation can help you increase production and expand manufacturing capabilities, contact us or explore our work samples here.

Related Products

Related Articles

FAQs About Large-Format 3D Printers

A large 3D printer, also known as a large-format or large-volume 3D printer, is a machine designed to produce oversized objects by adding material layer by layer. It works using additive manufacturing (AM) technology, where digital 3D models are sliced into thin layers, and the printer extrudes or deposits material to build the object from the ground up. This process is ideal for creating complex geometries, large-scale prototypes, and functional parts with high accuracy.

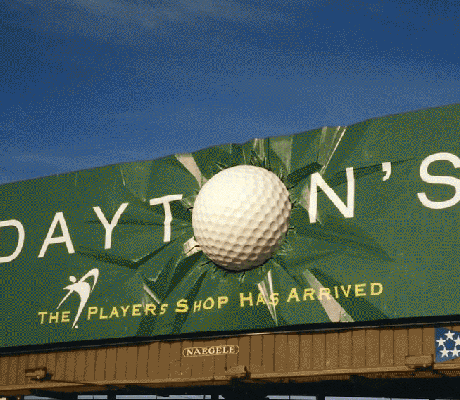

Large-format 3D printers are commonly used for creating massive structures such as architectural models, sculptures, props, molds, signage, and components for construction projects. These printers are also widely used in industries like aerospace, automotive, and industrial design for producing prototypes, tools, and custom parts. Their ability to handle large, intricate designs makes them ideal for various applications requiring significant scale and precision.

Selecting a large-volume 3D printer allows you to print sizable objects in one piece, reducing the need for assembly. This saves time and labor, increases design possibilities, and eliminates seams between parts, resulting in higher-quality output. Large 3D printers also offer flexibility in material usage and enable businesses to take on bigger, more complex projects that would be difficult or costly with traditional manufacturing methods.

The cost of large-scale 3D printers varies based on the machine’s size, capabilities, and features: print resolution, build volume, supported materials, and additional features like automation and software integration.

The size of objects you can print depends on the build volume of the 3D printer. For example, some large-format printers like FROGPRINT™ by Nexum have a build volume of up to several cubic meters, allowing for the creation of large sculptures, architectural models, or functional components in a single print. FROG3D® offers commercial financing options.

Industrial (commercial) 3D printers offer numerous advantages, including the ability to create highly detailed and accurate parts at a larger scale. They are ideal for producing durable, functional prototypes, customized components, and complex geometries that would be difficult to achieve with traditional manufacturing methods. Additionally, industrial printers offer greater efficiency, reduced material waste, and faster turnaround times, especially for low-volume or custom production runs.

3D printing technologies vary but include Fused Deposition Modeling (FDM), Stereolithography (SLA), Selective Laser Sintering (SLS), and Direct Metal Laser Sintering (DMLS). Large-format printers, such as those offered by FROG3D®, typically use FDM technology, where thermoplastic material is melted and extruded layer by layer to build the object.

Common materials used in 3D printing include plastics such as PLA, ABS, and PETG, as well as resins, and composites. Large-scale 3D printers, like FROGPRINT™, can print all of the commonly used plastic filaments, and Streamline Automation is happy to consult on the use of other additional materials.

Large-scale 3D printing presents several challenges, including longer print times, the need for specialized materials, and ensuring structural stability in oversized prints. Environmental factors such as temperature and humidity can also affect print accuracy and material performance. Before printing any project it is important to evaluate each project’s specific needs and requirements to determine the best approach.

The time it takes to print a large object depends on the size, complexity, and resolution of the design as well as the infill required for strength. A large-scale 3D print can take anywhere from several hours to several days to complete. Factors such as layer height, infill percentage, and the type of material used will also influence print time.

The power consumption of a large-format 3D printer varies depending on the machine’s size and technology. On average, a large-format printer can use anywhere from 500 watts to several kilowatts during operation. Energy consumption also depends on factors like the heating elements, extrusion systems, and build platform size.

While 3D printers can create complex and intricate designs, there are limitations to what they can produce. For example, large-format 3D printers are limited by their build volume, so extremely oversized objects may need to be printed in sections and assembled later. Additionally, 3D printers can struggle with producing very fine details or ultra-smooth surfaces without additional post-processing.

Certain materials and objects cannot be 3D printed. For instance, pure glass and some metals require highly specialized equipment, and objects with moving parts that require tight tolerances may not be easily produced in a single print. In addition, large-scale 3D printing may struggle with extremely intricate designs or objects that require the mechanical strength of certain traditional manufacturing methods.

The biggest objects created by 3D printers include architectural structures, large-scale sculptures, and even parts of buildings. One notable example is a 3D-printed pedestrian bridge in Spain, made entirely of concrete. Large-format printers like FROGPRINT™ by Nexum allow for similarly impressive projects, pushing the boundaries of what is possible with 3D printing technology.

Where Can You Buy a Large 3D Printer?

Many companies deal in large-volume 3D Printers. As Canada’s leading 3D fabrication solutions manufacturer, FROG3D® offers high-quality large-scale 3d printers in different sizes and configurations to meet your needs. You can browse our product catalog or fill out the contact form for more detailed information.

Helping our customers succeed.